Trusted shipping

Easy returns

Secure shopping

Buy Cable Ties by Avery Dennison USA Made Nylon Zip Ties Weather UV amp Impact Resistant Black Plastic Ties for Binding Bundling amp Organizing Cable amp Wire For Indoors amp Outdoors 11quot x 100 in United States - Cartnear.com

Cable Ties by Avery Dennison USA Made Nylon Zip Ties Weather UV amp Impact Resistant Black Plastic Ties for Binding Bundling amp Organizing Cable amp Wire For Indoors amp Outdoors 11quot x 100

CTNR1359158 CTNR1359158The Sharper Image

2027-01-12

/itm/cable-ties-by-avery-dennison-usa-made-nylon-zip-ties-weather-uv-amp-impact-resistant-black-plastic-ties-for-binding-bundling-amp-organizing-cable-amp-wire-for-indoors-amp-outdoors-11quot-x-100-1359158

USD

16.24

$ 16.24 $ 16.57 2% Off

Item Added to Cart

customer

*Product availability is subject to suppliers inventory

SHIPPING ALL OVER UNITED STATES

100% MONEY BACK GUARANTEE

EASY 30 DAYSRETURNS & REFUNDS

24/7 CUSTOMER SUPPORT

TRUSTED AND SAFE WEBSITE

100% SECURE CHECKOUT

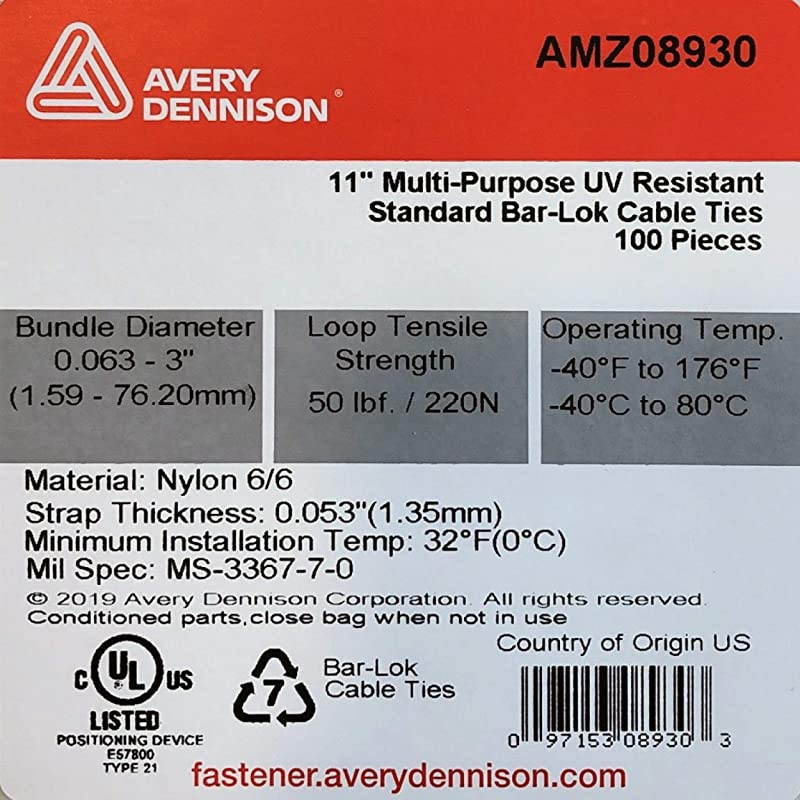

Style: 11" x 100SPECIFICATIONS

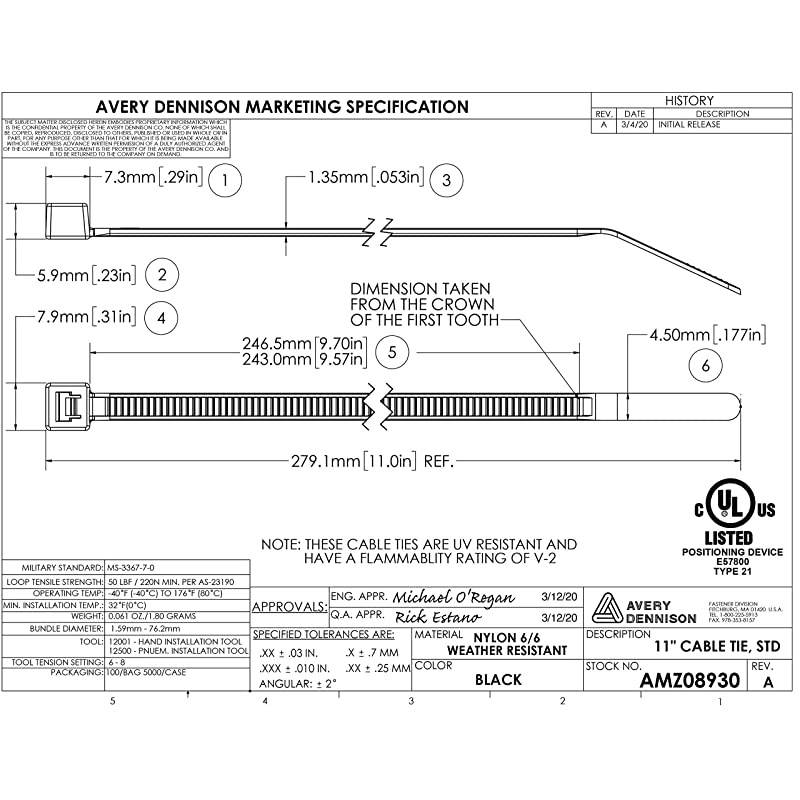

Strap Length: 11" ( 279.4 mm)Minimum

Tensile Strength: 50

lbs ( 22.68 kg)Width:.

177 ( 4.5 mm)Thickness:. 053 ( 1.35 mm)Bundle

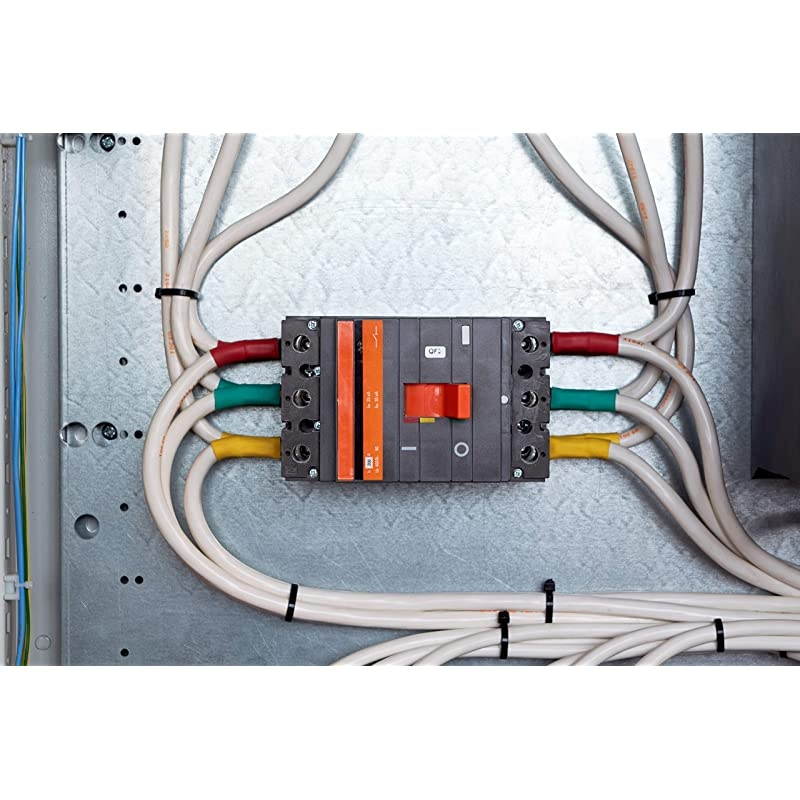

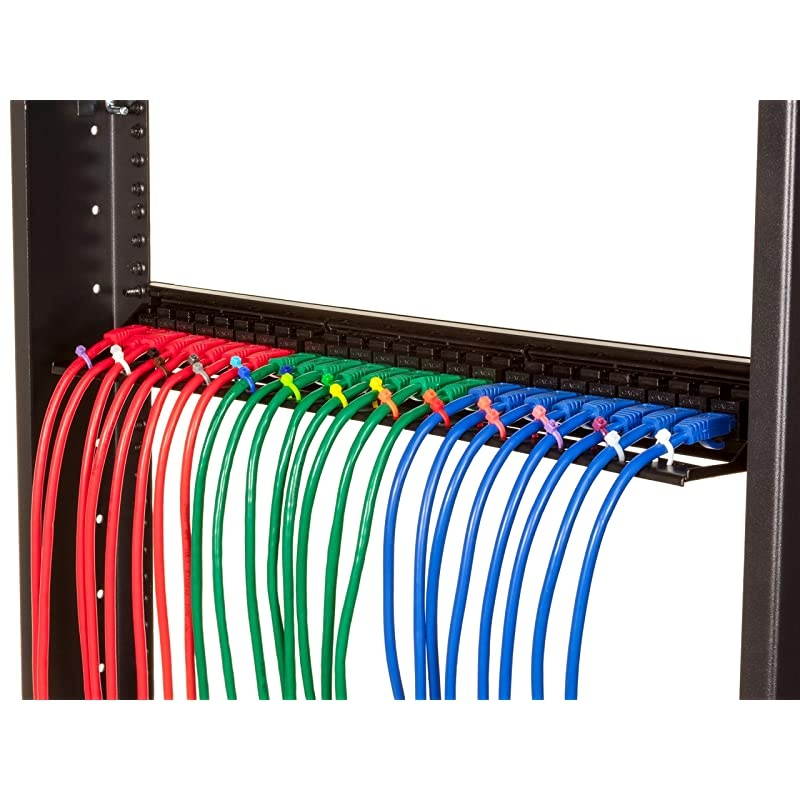

Range: 1/16 - 3 ( 1.59 mm 76.2 mm)Bundle, Secure, Position and AttachAvery Dennison manufactures cable ties for a wide range of needs. Safely secure items in a variety of environments including high heat, harsh weather and high vibration. They meet many qualifications for military specs and UL. Nylon Weather-Resistant ResinOur weather-resistant resin is used for outdoor applications because it has greater resistance to ultraviolet light. Ties contain 2% carbon black; temperature range is -40 F (-40 C) to 176 F (80 C). How a Cable Tie WorksWhen a user inserts the fastener tail into the head the cable tie forms a loop. The teeth of the cable tie should be to the inside of the head so that the strap enters the channel and the teeth slide against the pawl. The cable tie can be tightened by hand or with an installation tool, which can tighten and cut the portion of the strap not used in the loop. Cable Tie Performance CriteriaSome key performance criteria for a cable tie is the minimum loop tensile strength, the material, and the bundle diameter. The minimum loop tensile strength is expressed as the amount of force to cause the assembled tie to fail.

These values are typically expressed in pounds, kilograms and/or Newtons. If your application needs to secure big or heavy loads a higher tensile strength would be required. Lower tensile strengths can accomodate medium to light loads. Manufactured from type 6/6 Nylon, used because of its impact strength and resistance to abrasion and chemicals. Maximum and minimum bundle diameter are the limits in which the tie will function properly.

Strap Length: 11" ( 279.4 mm)Minimum

Tensile Strength: 50

lbs ( 22.68 kg)Width:.

177 ( 4.5 mm)Thickness:. 053 ( 1.35 mm)Bundle

Range: 1/16 - 3 ( 1.59 mm 76.2 mm)Bundle, Secure, Position and AttachAvery Dennison manufactures cable ties for a wide range of needs. Safely secure items in a variety of environments including high heat, harsh weather and high vibration. They meet many qualifications for military specs and UL. Nylon Weather-Resistant ResinOur weather-resistant resin is used for outdoor applications because it has greater resistance to ultraviolet light. Ties contain 2% carbon black; temperature range is -40 F (-40 C) to 176 F (80 C). How a Cable Tie WorksWhen a user inserts the fastener tail into the head the cable tie forms a loop. The teeth of the cable tie should be to the inside of the head so that the strap enters the channel and the teeth slide against the pawl. The cable tie can be tightened by hand or with an installation tool, which can tighten and cut the portion of the strap not used in the loop. Cable Tie Performance CriteriaSome key performance criteria for a cable tie is the minimum loop tensile strength, the material, and the bundle diameter. The minimum loop tensile strength is expressed as the amount of force to cause the assembled tie to fail.

These values are typically expressed in pounds, kilograms and/or Newtons. If your application needs to secure big or heavy loads a higher tensile strength would be required. Lower tensile strengths can accomodate medium to light loads. Manufactured from type 6/6 Nylon, used because of its impact strength and resistance to abrasion and chemicals. Maximum and minimum bundle diameter are the limits in which the tie will function properly.

![1/4’’ TRS Cable, [2-Pack 15FT] 1/4 Inch to 1/4 Inch 6.35mm Balanced Stereo Audio Cable for Studio Monitors,Mixer,Yamaha Speaker/Receiver,Black](https://cdn.cartnear.com/6d783ed2a2baf5362fe8e45112b7c8c2.jpg)