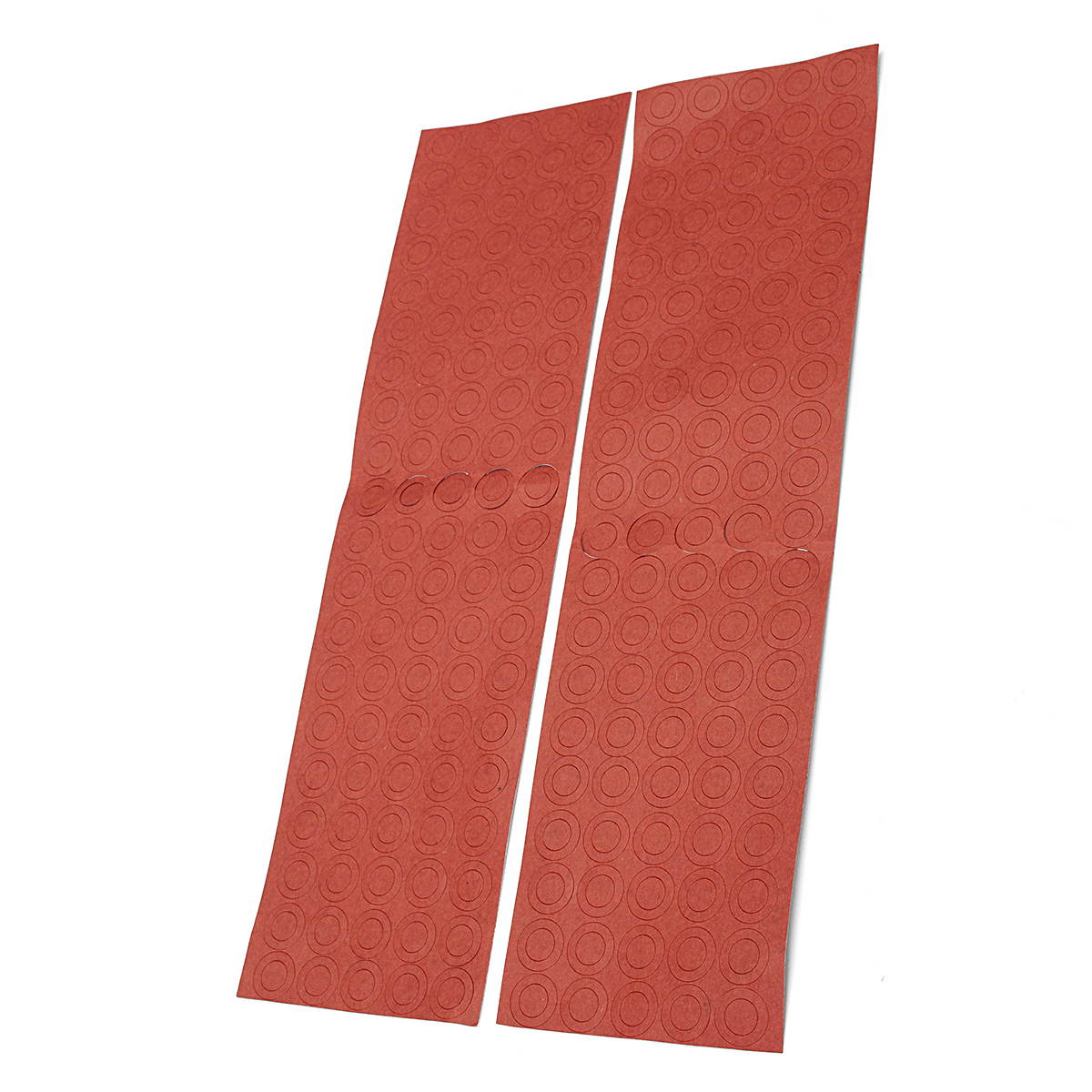

4000Pcs Cardboard 18650 Battery Insulators Electrical Insulating Adhesive Paper

Features: Outer Ring Diameter: 17mm/ 0.67" (appr. )Inner Ring Diameter: 10mm/ 0.39" (appr. )Thickness: 0.24 mm/ 0.01" (appr. )Package included: 4000Pcs Battery Insulators Adhesive Paper (Battery not included) 2 Sheets included, 100 insulators adhesive paper rings per sheet, total is 200 ringsAdhesive cardboard paper for 18650 battery insulator. Better protection to avoid short circuit on batteries. Easy peel and stick application. Package included:; 4000 x Battery Insulators Adhesive Paper

Good Wetting Epoxy, High Temperature, Fast Cure, Low Viscosity For Industrial & Sealing Applications, 2 Part, FS227, 10gm

- PRODUCT DESCRIPTION:

AA-BOND FS227 is a thixotropic polymer epoxy/polyamide system developed for industrial adhesive and sealing applications where the combination of high fill, easy handling, good wetting, toughness, and superior mechanical properties are required.

- GENERAL PROPERTIES

Appearance: Amber

Cure Type: Heat cure or Room temperature

Benefits:

+ High fill

+ Easy handling

+ Good wetting

+ Toughness

+ High temperature

+ Fast cure

+ Low viscosity

Operating Temperature: -60 to 110 °C

Substrates: Most material surfaces, including many metals, rigid plastics, glass, ceramics, leather, rubber, wood and concrete

- UNCURED PROPERTIES:

Viscosity @ 25 °C: 650

Specific Gravity, mixed: 1.12 g/cc

Pot Life: 75 minutes

- CURE SCHEDULE:

4 hours @ 65°C

24 hours @ 25°C

- CURED PROPERTIES:

Volume Resistivity: 1.20e+14 ohm-cm

Dielectric Strength: 460 volts/mil

Glass Transition Temp, Tg: 70 °C

Dielectric Constant: 3.35 @ Frequency 1000 Hz

Hardness, Shore D: 75

Lap shear: 2500 psi (Alum to Alum)

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

Call (888) 522-6742 For More Informations.

FDA Epoxy Medium Viscosity Class VI Approved Easily 1:1 Mixing For Catheters, Hearing Aids, Dental Products Biomedical Instruments & Devices FDA2, 2.5

PRODUCT DESCRIPTION:

AA-BOND FDA2 is a medium viscosity epoxy resin system specifically developed for medical device applications. It has been tested in accordance with USP biological reactivity tests, in vivo and received Class VI approval.

AA-BOND FDA2 is two part amber adhesive used and cured at room temperature for bonding, laminating and repair applications by manufacturers of food preparation, processing and packaging equipment and devices.

AA-BOND FDA2 provides low permeability to gases and vapors, and good resistance to water, weather, petroleum solvents, lubricants, to mild acids and alkalis, and to many other organic and inorganic compounds.

GENERAL PROPERTIES:

Appearance: Amber

Cure Type: Heat cure or Room Temperature

Benefits:

o Medium viscosity

o Class VI approved

o Easily mixed

o Low permeability

o Good resistance

Mix Ratio by weight: 100:100 / Resin:Hardener

Substrates: Most metals, ceramic, glass and plastics

Operating Temperature: -70 to 145 °C

Typical Applications: Bonding, laminating and repair applications by manufacturers of food preparation, processing and packaging equipment, and by manufacturers of catheters, hearing aids, dental products and other biomedical instruments and devices.

Minimum Service Temperature, Air -94 °F

UNCURED PROPERTIES:

Viscosity @ 25 °C: 14,000 ±2000

Specific Gravity, mixed: 1.11

Reactive solids contents, %: 100

Pot Life: 45 minutes

CURE SCHEDULE:

1-4 hours @ 65°C

24 hours @ 25°C

CURED PROPERTIES:

Glass transition temperature (Tg), °C: 54

Hardness, Shore D: 79

Dielectric strength volts/mil: 420

Water Absorption, %: .004

Lap shear strength, psi: 2700 (Aluminum to Aluminum)

GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

AVAILABILITY:

This epoxy can be supplied in various different packages.

Call (888) 522-6742 For More Informations.

Heat Resistant Epoxy Adhesive, 1:1 Mixing, Weather Resistant, Staking Components, Bonding, Laminating & Repair Applications Glue 28, 2.5gm

- PRODUCT DESCRIPTION:

AA-BOND 28 is a two part, heat-resistant and low exotherm, epoxy adhesive formulation. It is a 100% solid epoxy adhesive, with superior chemical resistance and shear strength.

AA-BOND 28 contains a thixotrophic agent which impedes thinning out of the material during heat cure when properly mixed and cured.

- GENERAL PROPERTIES

• Appearance Amber

• Cure Type Room temperature or Heat Cure

• Operating Temperature: -60 to 163 °C

• Mix Ratio by weight 100:100 / Resin:Hardener

• Typical Application(s):

Staking components, bonding, laminating and repair applications

• Benefits:

o Room temperature or Heat Cure

o Tough enamel like cure

o Bonds to a variety of substrates

o Weather resistant

• Substrates:

o Metals

o Glass

o Ceramics

o Wood and many plastics

- UNCURED PROPERTIES:

Specific Gravity, mixed 1.07

Reactive solids contents, % 100

Pot Life 60 minutes

- CURE SCHEDULE:

• 4 to 6 hours @ 65°C

• 24 hours @ 25°C

- MISC PROPERTIES:

• Shelf Life 2 years closed packaging

• Glass Transition Temp, Tg 93°C

• Hardness, Shore D 78

• Lap shear 2900 psi (Alum to Alum)

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

CALL (888) 522-6742 for more informations.

FDA Epoxy, Class VI Approved, 1:1 Mixing, For Bonding, Laminating & Repair Applications, Food Preparation, Processing & Packaging Equipment FDA2, 2.5g

PRODUCT DESCRIPTION:

AA-BOND FDA2 is a medium viscosity epoxy resin system specifically developed for medical device applications. It has been tested in accordance with USP biological reactivity tests, in vivo and received Class VI approval.

AA-BOND FDA2 is two part amber adhesive used and cured at room temperature for bonding, laminating and repair applications by manufacturers of food preparation, processing and packaging equipment and devices.

AA-BOND FDA2 provides low permeability to gases and vapors, and good resistance to water, weather, petroleum solvents, lubricants, to mild acids and alkalis, and to many other organic and inorganic compounds.

GENERAL PROPERTIES:

Appearance: Amber

Cure Type: Heat cure or Room Temperature

Benefits:

o Medium viscosity

o Class VI approved

o Easily mixed

o Low permeability

o Good resistance

Mix Ratio by weight: 100:100 / Resin:Hardener

Substrates: Most metals, ceramic, glass and plastics

Operating Temperature: -70 to 145 °C

Typical Applications: Bonding, laminating and repair applications by manufacturers of food preparation, processing and packaging equipment, and by manufacturers of catheters, hearing aids, dental products and other biomedical instruments and devices.

Minimum Service Temperature, Air -94 °F

UNCURED PROPERTIES:

Viscosity @ 25 °C: 14,000 ±2000

Specific Gravity, mixed: 1.11

Reactive solids contents, %: 100

Pot Life: 45 minutes

CURE SCHEDULE:

1-4 hours @ 65°C

24 hours @ 25°C

CURED PROPERTIES:

Glass transition temperature (Tg), °C: 54

Hardness, Shore D: 79

Dielectric strength volts/mil: 420

Water Absorption, %: .004

Lap shear strength, psi: 2700 (Aluminum to Aluminum)

GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

AVAILABILITY:

This epoxy can be supplied in various different packages.

Call (888) 522-6742 For More Informations.

Excellent Durability Adhesive, Heat & Impact Resistant FDA Epoxy, Medical Grade Medium Viscosity, FDA26, 5gm

- PRODUCT DESCRIPTION: AA-BOND FDA26 is Versatile adhesive guaranteed a high strength bond. AA-BOND FDA26 is two part adhesive used and cured at room temperature for bonding, repair applications by manufacturers of food preparation, processing and packaging equipment and devices. - PRODUCT PROPERTIES: Appearance: Grey Cure Type: Heat cure or Room temperature Benefits: * Excellent durability * High shear and peel strength * Heat and impact resistant * Handy duo-pack cartridges for easy mixing Mix Ratio by weight: 100:14 / Resin: Hardener Substrates: Most metals, ceramic, glass and plastics Operating Temperatures: -60 to 135 °C - UNCURED PROPERTIES: Viscosity @ 25 °C, cps: 17, 500 ±1000 @ temperature 77 °F, 25 °C Specific Gravity, mixed: 2.36 Reactive solids contents, %: 100 Pot Life: 50 minutes - CURE SCHEDULE: 1-4 Hours: @ 65°C 24 Hours: @ 25°C - CURED PROPERTIES: * Adhesive Bond Strength, psi: o 2120 ( 1 hr @ 65°C) o 2190 (24 hrs @ 25°C) * Hardness, Shore D: o 86 (24 HR @ 25°C) o 90 (1 hr @ 65°C) - THERMAL PROPERTIES: Glass transition temperature (Tg): 113°C, 235 °F - GENERAL INFORMATION: For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS). AVAILABILITY: This epoxy can be supplied in various different packages. Call (888) 522-6742 For More Informations.

200Pcs Cardboard 18650 Battery Insulators Electrical Insulating Adhesive Paper

Features: Outer Ring Diameter: 17mm/ 0.67" (appr. )Inner Ring Diameter: 10mm/ 0.39" (appr. )Thickness: 0.24 mm/ 0.01" (appr. )Package included: 200Pcs Battery Insulators Adhesive Paper (Battery not included) 2 Sheets included, 100 insulators adhesive paper rings per sheet, total is 200 ringsAdhesive cardboard paper for 18650 battery insulator. Better protection to avoid short circuit on batteries. Easy peel and stick application. Package included: 200 x Battery Insulators Adhesive Paper

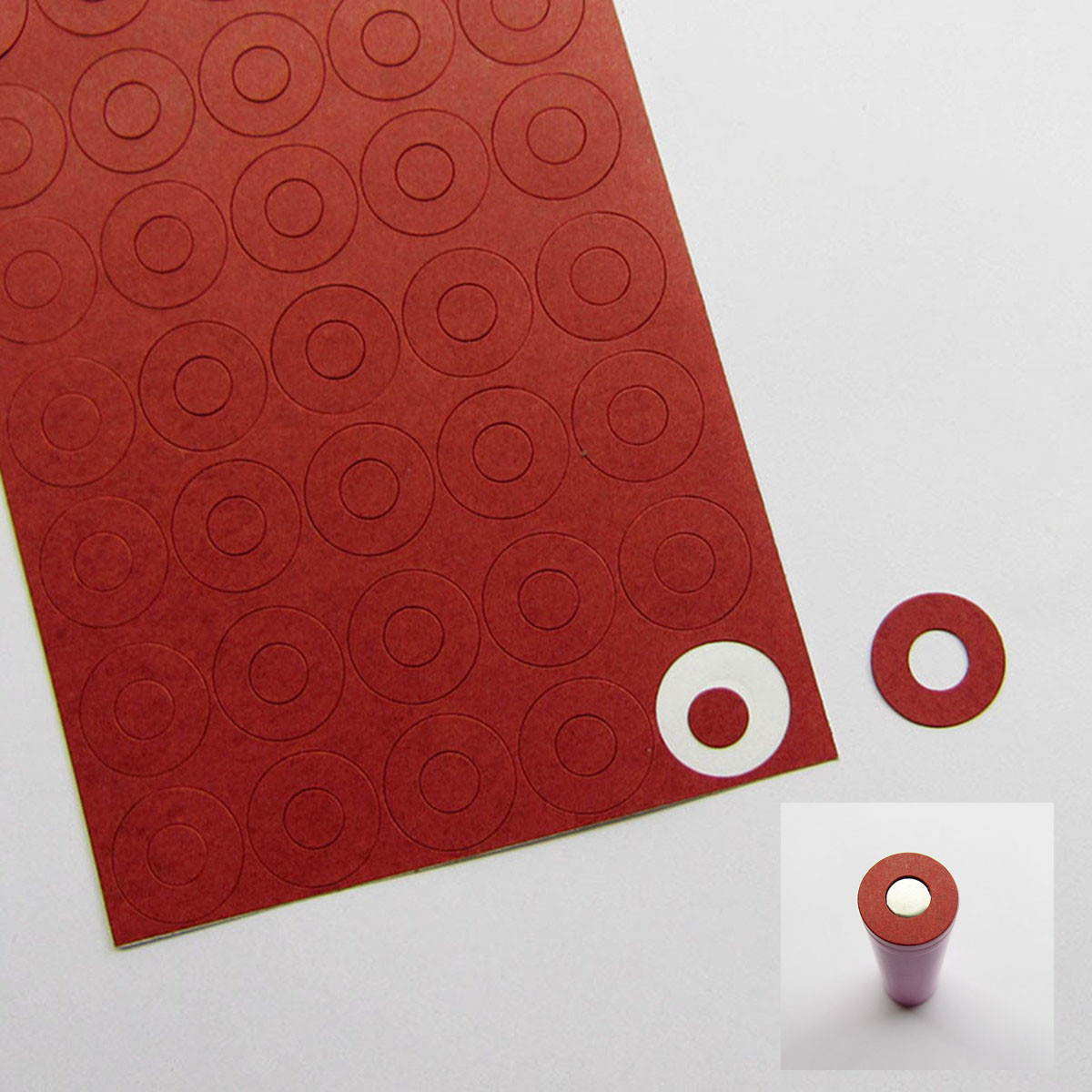

Highside - HS10001 Leak Lock Lock Joint Sealing Compound

Highside = 1-1/3 oz Tube Highside® Leak Lock is a state-of-the-art high strength, pipe joint sealant consisting of chemically resistant film formers, plasticizers, reinforcing fillers and solvents, useable on all clean metal or plastic surfaces. A resin based soft setting brushable paste pipe joint compound resistant to all refrigerants, oils, water and most chemicals, liquids and gases. Use with pressures from 10, 000 PSI to full vacuums Temperature range -200°F to 400°F It never hardens and it never becomes brittle Ideal for joining all metals, plastics and other materials Will stick to all clean surfaces Prevent vibration from loosening nuts, bolts, plugs and fittings 1-1/3 ounce tube Non-toxic

5cmx20m Adhesive Car Aluminium Sealing Foil Tape Stripe Resist Duct Repair Tools

Features: Heat insulation, temperature stability. Strong adhesive force. No harmful substance. Not easy to corrosion. Reduce noise. It is not easy to wear. Soft and strong expansion. Anti pollution ability strong surface.; Specification: Material: AluminiumColour: ChromeThicknes: 0.06 mmWidth: 5cmTotal Length: 20mTemperature resistance: 90? (Long term) 120°C (Short term); Package includeds: 1 x Foil Tape; Details pictures:

5cmx20m Adhesive Car Aluminium Sealing Foil Tape Stripe Resist Duct Repair Tools

Features: Heat insulation, temperature stability. Strong adhesive force. No harmful substance. Not easy to corrosion. Reduce noise. It is not easy to wear. Soft and strong expansion. Anti pollution ability strong surface.; Specification: Material: AluminiumColour: ChromeThicknes: 0.06 mmWidth: 5cmTotal Length: 20mTemperature resistance: 90? (Long term) 120°C (Short term); Package includeds: 1 x Foil Tape; Details pictures:

High Temperature Adhesive, Fast Cure Epoxy, Low Shrinkage & Viscosity, 2 Part Fiber Optic Connectors Assembly, Multimode & Single Mode Connectors F125

- PRODUCT DESCRIPTION:

AA-BOND F125 is a 8 minutes gelling epoxy recommended for use in fiber optic connectors, optical and industrial bonding applications.

AA-BOND F125 is clear, two part system is easily mixed and used at room temperature. Fiber optic connectors can be polished in as little as 15 to 20 minutes for piston free assurance. The high bond strength of AA-BOND F125 to glass, plastics, ceramics, metals and masonry allows it to be used in a wide array of applications including lens bonding, connector backfills, construction, component assembly and maintenance repair.

AA-BOND F125 is low shrinkage epoxy, develops significant properties 1 hour after mixing. However, an extended cure of 4-6 hours at 25°C is required for fully matured bonds.

NOTE: AA-BOND F125 develops a high exotherm. Use immediately after mixing. The exothermic reaction begins within 2 minutes after initiating the mixing step, so have everything ready before mixing.

- GENERAL PROPERTIES:

• Components: 2 component - requires mixing

• Mix Ratio by weight: 100:95 / Resin:Hardener

• Benefits:

o Low viscosity

o Fast Cure

o Low shrinkage

• Cure Type: Room temperature or Heat cure

• Operating Temperature :-60 to 100 °C

• Typical Applications: Fiber optic assembly, multimode and single mode connectors, small potting and sealing applications

- UNCURED PROPERTIES:

• Viscosity @ 25 °C:

o Resin: 9000cP

o Hardener: 14000cP

• Specific Gravity :1.19

• Pot Life: 5 minutes

- CURE SCHEDULE:

• 24 hours @ 25°C

• 1 hour @ 60°C

- CURED PROPERTIES:

• Glass Transition (Tg), ultimate, °C: 40

• Hardness, Shore D: 75

• Tensile Shear, alum to alum, psi: 2800

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

CALL (888) 522-6742 for more informations.

Flexible Silver Epoxy, Cold Solder, Electrically Conductive Adhesive, Circuits, Electrical Modules, Wave Guides, Flat Cable & High Frequency Shields R

- PRODUCT DESCRIPTION:

AA-DUCT 916 is an electrically conductive, silver-filled epoxy formulation recommended for electronic bonding, coating, and sealing applications that require high flexibility coupled with good electrical and mechanical properties.

AA-DUCT 916 is two-part, smooth paste adhesive of refined pure silver and epoxy resin components. It is free of solvents and copper or carbon additives. It develops strong, durable, resilient, electrically and thermally conducting bonds and coatings between many different and dissimilar materials such as metals, ceramics, glass and plastic insulates.

AA-DUCT 916 cures at room temperature and can be used as a flexible "cold-solder" for heat-sensitive components where hot-soldering is impractical. It also can be used for the assembly and repair of electrical modules, flexible circuits, wave guides, flat cable and high frequency shields.

- PRODUCT DESCRIPTION

Appearance Silver

Cure Type Heat cure or Room temperature

Benefits High strength

Perfect bond

Cold solder for heat sensitive components

Mix Ratio by weight 100:115 / Resin:Hardener

Substrates Excellent choice aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards.

- UNCURED PROPERTIES:

Viscosity @ 25 °C cps Paste

Specific Gravity, mixed 2.85

Reactive solids contents, % 100

Pot Life 3 hours

Shelf life 1 year

- CURED PROPERTIES:

Hardness, Shore D 64

Volume Resistivity ohm. cm

Electronic Industries Epoxy, Special Formulation Adhesive For PCB Components & Assembly, Aerospace, 2 Part, Thixotropic 2104, 2.5gm

- PRODUCT DESCRIPTION:

AA-BOND 2104 is a thixotropic epoxy system recommended for critical electronics, aerospace and industrial bonding, laminating and reinforcing applications requiring an adhesive with high-fill, non-sag characteristics.

AA-BOND 2104 solvent-free adhesive is easily mixed and used for staking components to printed circuit boards for enhanced mechanical rigidity, and for bonding, laminating and repair applications involving metals, glass, ceramics, wood and many plastics.

AA-BOND 2104 hardens to a tough, enamel-like coating offering good chemical resistance as well as superior physical and mechanical properties.

AA-BOND 2104 provides good electrical insulation and resistance to weather, galvanic action, petroleum products and lubricants, alcohol, salts, mild acids and alkalis, and other organic and inorganic compounds.

- GENERAL PROPERTIES:

Appearance: Milky translucent

Cure Type: Room temperature or Heat cure

Benefits:

* Great for Aerospace applications

* Great for reinforcing applications

* Bonds to many substrates

Mix Ratio by weight : 100:22 / Resin:Hardener

Substrates Staking components, bonding, laminating, repair applications, metals, glass, ceramics, wood and many plastics

Operating Temperature: -40 to 125 °C

Typical Application(s):

PCB components, aerospace, anything where superior properties are required

- UNCURED PROPERTIES:

Solids Content: 100%

Specific Gravity, mixed: 1.19 g/cc

Pot Life: 30 minutes

- CURE SCHEDULE:

4 hours @ 65°C

24 hours @ 25°C

MISC PROPERTIES:

Hardness, Shore D 88

GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

AVAILABILITY:

This epoxy can be supplied in various different packages.

CALL (888) 522-6742 for more information.

Super Electrically Conductive Silver Epoxy For Microwave EMI & RFI Shielding, Wave Guides, PCB, Electronic Modules, One Part 905-10gm

- PRODUCT DESCRIPTION:

AA-DUCT 905 is a single component epoxy, formulated with pure silver powder combined with organic binders and solvents to produce electrically conductive paths, films or patterns over non-conductive substrates.

AA-DUCT 905 shows slight settling when stored for a long period of time, no caking and will re disperse to a smooth homogeneous state.

AA-DUCT 905 formulation produces electrically conductive paths on a wide variety of surfaces including plastics, rubber, cloth, thermoplastic, paper, wood and many others.

AA-DUCT 905 designed for use in diversified applications as microwave EMI & RFI shielding, in the assembly or repair of printed circuit boards, wave-guides, electronic modules, flat cable, static shielding, connections, and circuitry. This Epoxy is designed for screening and micro product adhesion applications.

- PRODUCT PROPERTIES:

Appearance : Silver

Cure Type: Heat cure

Benefits:

• High strength

• Perfect bond

• EMI & RFI shielding

• Wave guides

Substrates:

• Integrated Circuits

• Aluminum

• Copper

• Magnesium

• Steel

• Bronze

• Nickel

• Kovar

• Ceramic

• Glass

• Phenolic

• G-10 epoxy glass boards.

Catalyst: Anhydride

Hardness, Shore D: 83

- AVAILABILITY:

This epoxy can be supplied in many different packages.

CALL (888) 522-6742 for more informations.

Nu-Calgon 4296-50 - Pan-Spray™ Leak Sealer - White Color - 16 Ounce Aerosol

Pan-Spray is an effective, easy-to-use water proof rubberized coating that won't chip, flake, or peel. It's ideal for sealing out rust and corrosion as well as repairing leaky condensate pans, cooling towers, swamp coolers, roofing, gutters, and down spouts. Pan Spray is the perfect solution for emergency and permanent repair. It is a quick, easy and economical repair on troublesome leaks. Use on condensate pans, swamp coolers, humidifier pans, plumbing and pipe fixtures, roofing, downspouts or gutters. Reliable rubberized coating Quick and economical answer to repair troublesome leaks Temperature range 10ºF to 250ºF Stays flexible and won't freeze or sag Contains no CFC's Dries in 20 to 30 minutes Ideal for sealing out both rust and corrosion Can be painted

AC/SMART SEAL™ - 1175 - No-Acid - Acid Neutralizer For Air Conditioning And Refrigeration Systems

No-Acid - Acid Neutralizer For Air Conditioning And Refrigeration Systems

Nickel Adhesive Electrically Conductive Epoxy, 1 Part, Heat Cure Only, Fast Cure, Ease In Handling, Passes NASA’s Outgassing For EMI RFI Shielding,

- PRODUCT DESCRIPTION: AA-DUCT N02 is a single component, heat curing, conductive epoxy polymer that was designed for ease in handling. This high performance conductive polymer cures quickly at elevated temperatures making it ideally suited for rapid Processing and assembly. AA-DUCT N02 passes NASA’s outgassing testing (ASTM E-595) and is listed in NASA’s Outgassing Data for Selecting Spacecraft Materials list. AA-DUCT N02 offers excellent mechanical, electrical, and physical properties at continuous operating Temperatures up To 175°C. This versatile nickel conductive adhesive can be used for chip bonding in Micro and electronic hybrid circuit Fabrication. This unique conductive polymer also exhibits outstanding adhesion to a wide variety of substrates with good hot strength at intermittent temperatures up to 325°C. AA-DUCT N02 has also been used in microwave applications for EMI and FRI shielding, for assembly and repair of circuit boards and Electronic component manufacturing. - PRODUCT DESCRIPTION: Base: Epoxy Appearance: Grey Cure Type: Heat cure or Room temperature Mix Ratio by weight: 100:6 / Resin: Hardener Substrates Excellent choice aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards. Operating Temperature: -60 to 110 °C Viscosity @ 25 °C cps Soft: Paste Shelf Life: 6 months - CURED PROPERTIES: Hardness, Shore D: 88 Volume Resistivity ohm-cm: 3.8 x 10-2 - CURE SCHEDULE: 2 Hours @ 125 °C 1 hour @ 150°C 30 min @ 175 °C - THERMAL CHARACTERISTICS: Thermal Conductivity, Btu/hr/ft2/°F/in: 10.1 Operating Temp. Range, °C: -55 to +175 - NASA OUTGASSING RESULTS: TML (Total Mass Loss): % 0.25 CVCM (Collected Volatile Condensable Materials): % 0.00 WVR (Water Vapor Recovery): % 0.07 - GENERAL INFORMATION: For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS). - AVAILABILITY: This epoxy can be supplied in various different packages. - PRODUCT DESCRIPTION: AA-DUCT CG2 is a single component epoxy, formulated with silver coated ceramic that results in lower material costs without adversely sacrificing the properties obtained with a pure silver formulation. This concept opens the door to a wide range of applications previously prohibited by the much higher cost of Conventional silver conductive. AA-DUCT CG2 Formulated with Silver coated ceramic power combined with organic binders and solvents to produce electrically conductive paths, films or patterns over non-conductive substrates. AA-DUCT CG2 formulation produces electrically conductive paths on a wide variety of surfaces including plastics, rubber, cloth, thermoplastic, paper, wood and many others. AA-DUCT CG2 designed for use in diversified applications as microwave EMI & RFI shielding, in the assembly or repair of printed circuit boards, waveguides, electronic modules, flat cable, static shielding, connections, and circuitry. - GENERAL INFORMATION: Appearance: Silver Coated ceramic %Silver coated ceramic: 76 Cure Type: Heat cure Benefits: - High strength - Perfect bond - EMI & RFI shielding - Wave guides Substrates: Excellent choice fo

Good Electrical Insulation Epoxy, Smooth Paste Adhesive for Fiber Optic Connectors, Photonic & Electronic Applications, LED Displays, Lenses F162, 250

- PRODUCT DESCRIPTION:

AA-BOND F162 is a thixotropic electrical insulating epoxy adhesive system with low vapor pressure and outgassing characteristics.

AA-BOND F162 was specifically developed for fiber optic, laser, photonic and electronic applications requiring excellent electrical insulation in combination with effective thermal dissipation from heat-producing components.

AA-BOND F162 is two-part epoxy compound develops strong, durable, stable, high impact thermally conductive bonds at room temperature, and adheres readily to itself, and to metals, many plastics, silica, steatite, alumina, sapphire and other ceramics, glass, and to many other materials.

AA-BOND F162 provides excellent resistance to salt solutions, mild acids and alkalis and many other chemicals including petroleum solvents, lubricating oils and alcohol.

- GENERAL PROPERTIES:

• Appearance: Ligh grey/off white

• Cure Type: Room Temperature or Heat cure

• Benefits:

o Smooth paste

o Fiber optic

o Laser

o Photonic and electronic applications

o Good electrical insulation

• Mix Ratio by weight: 100:10 / Resin:Hardener

• Substrates: Metals, Many plastics, Glass, and other materials

• Operating Temperature: -60 to 120 °C

• Typical Applications: ALL types of fiber-optic connectors as well as LED displays, lenses and other optical components.

• Max Temperature: 125 °C

- UNCURED PROPERTIES:

• Viscosity @ 25 °C: Paste

• Thixotropic Index: 1.0

• Specific Gravity, mixed, g/cc: 2.29

- CURE SCHEDULE:

• 2-4 hours @ 65°C

• 24 hours @ 25°C

- CURED PROPERTIES:

• Thermal Conductivity: 6.09 BTU-in/hr-ft²-°F

• Hardness, Shore D: 88

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

Call (888) 522-6742 For More Informations.

Effective Thermal Coupler Grease, Thermally Conductive, For Cooling, thermal management, Telecommunications, Hardware AA-GREASE 04, 500gm Jar

- PRODUCT DESCRIPTION: AA-GREASE 04 is an opaque white heat sink grease compound, which is applied to the base and mounting studs of transistor and diodes to provide a positive heat sink seal, this facilitates heat transfer away from electrical/electronic components and into heat sinks, thereby increasing the overall efficiency and performance of the device. AA-GREASE 04 is silicone material, heavily filled with efficient heat conductive zinc oxide and a binding agent, this combination promotes high thermal conductivity, high temperature stability, and the lowest amount of bleed and evaporation. AA-GREASE 04 thermal compound resists changes in consistency temperatures up to 180°C; function as heat transfer media, durable dielectric insulation, barrier against environmental contaminants and as a stress-relieving shock and vibration absorber over a wide temperature and humidity range. AA-GREASE 04 thermal paste is resistant to ozone and ultraviolet degradation and has good chemical and solvent stability, good interference between the heat producing device and the heat transfer media, and low surface tension that enables them to wet most surfaces. AA-GREASE 04 will not harden, dry, or melt after 1200 hours @ 205°C. - ELECTRICAL PROPERTIES: Dielectric Strength, volts/mil (ASTM D 150): 390 Dielectric Constant @ 100Hz (ASTM D150): 4.40 Dissipation Factor @ 100Hz (ASTM D150): 0.0021 Volume Resistivity, ohm-cm (ASTM D257): 2.9 x1014 - THERMAL PROPERTIES: Thermal Conductivity W/m-K 0.88 Operating Temperature Range, °C -60 to 205 Thermal Resistance °C-In2 /W 0.05 - LIMITATIONS: AA-GREASE 04 is neither tested nor represented as suitable for medical or pharmaceutical use. - CLEAN UP & DISPOSAL: AA-GREASE 04 can be removed by using solvents such as mineral spirit, heptane, or isopropyl alcohol. Dispose of in accordance with local, state and federal regulations for hazardous waste. - TYPICAL PROPERTIES AND CHEMICAL CHARACTERISTICS: Color: White Base Fluid: Dimethyl Polysiloxane Filler: Zinc oxide Specific Gravity, 25°C, gm/cc: 2.45 Viscosity: Paste Press Flow @ 42.5 PSI, 25°C sec: 13 Penetration (Worked), mm: 2851/10 Evaporation 24 hrs @25°C, %: 0.0 Evaporation @ 200°C 24H by weight, %: 0.5 Bleed 24 Hours, %: 0.6 - STORAGE HANDLING & SHELF LIFE: AA-GREASE 04 has a shelf life of 5 years at room temperature (76°F) in an unopened container, settlings may occur during long term storage, it is recommended to re-mix the filler by hand or mechanical mixing. Keep container tightly closed store in cool area away from ignition sources and oxidizers, no special precautions need to be taken if product is handled according to directions. Shelf AA-GREASE 04 is neither tested nor represented as suitable for medical or pharmaceutical use. - POTENTIAL USES: • Effective thermal coupler for any heat sink device, CPU to heat sink. • Automotive temperature-sensing devices. • Temperature sensors. • Applied to the base and mounting studs of transistor, diodes and silicone controlled rectifiers. • Power transistors. • Diodes, semiconductors. • Thermal Joints. • For any device where efficient cooling is required. • Potting. • TEC Modules. • Hardware. • Telecom

Electrical Insulator Epoxy For Bonding, Laminating, Equipment, Hearing Aids, Dental Products, Biomedical Instruments Device FDA22, 100 gm Pouch

- PRODUCT DESCRIPTION:

AA-BOND FDA22 is a high viscosity epoxy resin system specifically developed for bonding and coating applications in accordance with Title 21, U.S. Code of Federal Regulations, Food and Drug Administration (FDA) Chapter 1, Sub Part B, Sections 175.105 and 175.300.

AA-BOND FDA22 is two-parts tan adhesive is easily mixed, used and cured at room temperature for bonding, laminating and repair applications by manufacturers of food preparation, processing and packaging equipment, and by manufacturers of catheters, hearing aids, dental products and other biomedical instruments and devices.

AA-BOND FDA22 is an effective electrical insulator, and it provides low permeability to gases and vapors, and good resistance to water, weather, galvanic action, to petroleum solvents, lubricants and fuels, to mild acids and alkalis, and to many other organic and inorganic compounds

- PRODUCT PROPERTIES:

Appearance: Light Tan

Cure Type: Heat cure or Room temperature

Benefits:

• High viscosity

• Easily mixed

• Electrical insulator

• Low permeability

• Good resistance

Mix Ratio by weight: 100:40 / Resin:Hardener

Substrates: Most metals, ceramic, glass and plastics

Operating Temperatures: -70 to 145 °C

- Typical Applications:

Bonding, laminating and repair applications by manufacturers of food preparation, processing and packaging equipment, and by manufacturers of catheters, hearing aids, dental products and other biomedical instruments and devices.

- UNCURED PROPERTIES:

Viscosity @ 25 °C, cps: 27,000

Thixotropic Index: 1.2

Specific Gravity, mixed: 1.44

- CURED PROPERTIES:

Hardness, Shore D: 78

CTE, Linear: 26.1 µin/in-°F

Dielectric strength kv/in: 420

Volume Resistivity ohm-cm: 1.50e+14

Elongation at Yield: 5.0 %

Adhesive Bond Strength : 2100 psi Lap shear, alum to alum

- ELECTRICAL PROPERTIES:

Volume Resistivity: 1.50e+14 ohm-cm

Dielectric Constant: 3.5 @ frequency 1000 Hz

Dielectric Strength: 420 kV/in

Dissipation Factor: 0.020 @ frequency 1000 Hz

- CURE SCHEDULE:

1-4 Hours @ 65°C

24 to 36 Hours @ 25°C

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

Call (888) 522-6742 For More Informations.

FDA Epoxy Adhesive, Medical Grade Medium Viscosity, AA-BOND FDA26, 100gm

- PRODUCT DESCRIPTION: AA-BOND FDA26 is Versatile adhesive guaranteed a high strength bond. AA-BOND FDA26 is two part adhesive used and cured at room temperature for bonding, repair applications by manufacturers of food preparation, processing and packaging equipment and devices. - PRODUCT PROPERTIES: Appearance: Grey Cure Type: Heat cure or Room temperature Benefits: * Excellent durability * High shear and peel strength * Heat and impact resistant * Handy duo-pack cartridges for easy mixing Mix Ratio by weight: 100:14 / Resin: Hardener Substrates: Most metals, ceramic, glass and plastics Operating Temperatures: -60 to 135 °C - UNCURED PROPERTIES: Viscosity @ 25 °C, cps: 17, 500 ±1000 @ temperature 77 °F, 25 °C Specific Gravity, mixed: 2.36 Reactive solids contents, %: 100 Pot Life: 50 minutes - CURE SCHEDULE: 1-4 Hours: @ 65°C 24 Hours: @ 25°C - CURED PROPERTIES: * Adhesive Bond Strength, psi: o 2120 ( 1 hr @ 65°C) o 2190 (24 hrs @ 25°C) * Hardness, Shore D 86 (24 HR @ 25°C) * 90 (1 hr @ 65°C) - THERMAL PROPERTIES: Glass transition temperature (Tg) 113°C, 235 °F - GENERAL INFORMATION: For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS). AVAILABILITY: This epoxy can be supplied in various different packages. Call (888) 522-6742 For More Informations.

High Impact Epoxy, Two Part Adhesive, Medium Viscosity, AA-BOND 2135 , 100gm kit

This is a medium viscosity epoxy adhesive recommended for bonding, laminating, sealing, and structural repair applications where easy mixing and good wetting combined with high impact strength properties are required. This superior, two-part adhesive is easily mixed and handled at room temperature, and develops strong, tough, high performance bonds to metals, ceramics, wood, concrete, phenolics, polyesters, epoxies, many urethanes and other plastics, and to many other materials. Fully cured this product is a tough, durable, electrically insulating adhesive with excellent mechanical, impact and shock resistance properties. In addition, it provides good resistance to gases, vapors, weather, water, petroleum solvents, anti-icing fluids, salt solutions, many mild acids and alkalis, and many other organic materials. Easy mix pre-measured pouch. Simple mix and use without any mess.

Metal Repair Epoxy, Steel filled Adhesive, High Performance, AA-BOND FS313 , 100gm kit

PRODUCT DESCRIPTION:

This Product is steel epoxy, tooling resin features a highly filled, low viscosity composition for low shrinkage,can be easily drilled, tapped, polished, milled, sawed, or turned on a lathe, with conventional metal-working tools. This unique resin system is recommended for the fabrication of metal and vacuum form molds, hammer forms, drop hammer dies, foundry patterns, master molds, core filling, draw and stretch dies, lay-up molds, etc. Easy mix pre-measured pouch. Simple mix and use without any mess.

Food & Drug Administration Medical Grade Epoxy, Electrically Insulating, Food Preparation Processing & Packaging Adhesive FDA2T, 100gm

- PRODUCT DESCRIPTION:

AA-BOND FDA2T is a thixotropic epoxy resin system specifically developed for medical device applications. It has been tested in accordance with USP biological reactivity tests, in vivo and received Class VI approval.

AA-BOND FDA2T is an effective electrical insulator, and it provides low permeability to gases and vapors and good resistance to water, weather, lubricants and fuels, to mild acids and alkalis, and many other organic and inorganic compounds.

- PRODUCT PROPERTIES:

Appearance: Amber

Cure Type: Heat cure or Room Temperature

Benefits:

Medium viscosity

Electrically Insulating

Low permeability to gases and vapors

Low temperature cure

Mix Ratio by weight: 100:93 / Resin: Hardener

Typical Applications: Medical, Food preparation processing and packaging

- UNCURED PROPERTIES:

Viscosity @ 25 °C, cps: 25000 ±1000

Specific Gravity, mixed: 1.119

Pot Life: 3 hours

- CURE SCHEDULE:

1 to 4 Hours @ 65°C

24 Hours @ 25°C

- THERMAL PROPERTIES:

CTE, linear: 29.4 µin/in-°F @ temperature 68 °F

Glass Transition Temp, Tg: 70.0 °C, 158 °F

Operating Temperature :-70 to 145 °C

- CURED PROPERTIES:

Coefficient of Thermal Expansion, cm/cm/ºC: 5.30×10-05

Hardness, Shore D: 79

Elongation at Yield: 9.0 %

Adhesive Bond Strength :1800 psi

- ELECTRICAL PROPERTIES:

Volume Resistivity: 1.20e+14 ohm-cm

Dielectric Constant: 3.4 @ frequency 1000 Hz

Dielectric Strength: 420 kV/in

Dissipation Factor: 0.020

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

Call (888) 522-6742 For any Question.

Good Electrical Insulation Epoxy For PCB Staking Electronics Aerospace Industrial Bonding Laminating Repair Applications 2112, 100gm

- PRODUCT DESCRIPTION:

AA-BOND 2112 is a thixotropic epoxy system recommended for critical electronics, aerospace and industrial bonding, laminating and reinforcing applications requiring an adhesive with high-fill, non-sag characteristics.

AA-BOND 2112 solvent-free adhesive is easily mixed and used for staking components to printed circuit boards for enhanced mechanical rigidity, and for bonding, laminating and repair applications involving metals, glass, ceramics, wood and many plastics.

AA-BOND 2112 hardens to a tough, enamel-like coating offering good chemical resistance as well as superior physical and mechanical properties. The cured adhesive provides good electrical insulation and resistance to weather, galvanic action, petroleum products and lubricants, alcohol, salts, mild acids and alkalis, and other organic and inorganic compounds.

- GENERAL PROPERTIES:

• Appearance: Milky translucent

• Cure Type: Room temperature or Heat Cure

• Benefits:

o Tough enamel like cure

o Bonds variety of substrates

o Good electrical insulation

o Weather resistant

Mix Ratio by weight: 100:22 / Resin:Hardener

Substrates:

Metals, glass, ceramics, wood and many plastics

Operating Temperature : -60 to 125 °C

Typical Applications:

Printed circuit board repair, staking components, bonding, laminating and repair applications.

- UNCURED PROPERTIES:

Viscosity @ 25 °C, mPa·s (cP) 60000 cPs

Thixotropic Index 6.5

Specific Gravity, mixed 1.2

Reactive solids contents, % 100

Pot Life 30 minutes

- CURE SCHEDULE:

4 hours @ 65°C

24 hours @ 25°C

- MISC PROPERTIES:

• Volume Resistivity 6.00e+13 ohm-cm

• Dielectric Constant 4.6

• Dielectric Strength 16.1 kV/in

• CTE, linear: 55.0 µm/m-°C@ Temperature 20.0 °C

• Glass Transition Temp, Tg 93 °C

• Hardness, Shore D 90

• Lap shear 1900 psi (Alum to Alum)

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

CALL (888) 522-6742 for more information.

TRADEPRO® Clam Shell With 1/4" Adapter A/C Leak Freeze 1.5 oz, 10 x 7 x 1.5

The leading air conditioning and refrigerant leak repair solution in the US today. All products are OEM Approved and Made in the USA. AC Leak Freeze is ideal for preventative maintenance and leak protection.

High Temperature Adhesives, Fast Cure Epoxy, Low Viscosity, Fiber Optic, Connectors, Small Potting & Sealing Applications, 2 Part, F123BK 100gm

- PRODUCT DESCRIPTION:

AA-BOND F123BK is a low viscosity, two-component epoxy formulation that signals both proper mixing and curing when bonding fiber optic bundles, potting glass fibers, and/or terminating single or multi-channel fiber optic connectors. It exhibits good wicking, and develops strong, tough, mechanically stable bonds to a wide variety of fiber optic and optical materials that includes most metals, ceramics, glass and many plastics.

AA-BOND F123BK has good impact and thermal shock resistance, and yields excellent low stress, pot-and-polish connections which do not piston during cycle tests. It is also resistant to water and weathering, vapors and gases, most petroleum products, and an extended range of organic and inorganic environments. Shorter cures at higher temperatures (e.g. 2 minutes at 120°C or 1 minute at 150°C) are also possible. An additional post-cure of 30 minutes at 150°C is recommended when application temperatures higher than 150°C are anticipated.

- GENERAL PROPERTIES:

• Color: Black

• Components: 2 component - requires mixing

• Mix Ratio by weight: 100:10 / Resin:Hardener

• Benefits:

o Low viscosity

o Thermal shock and impact resistant

o Low stress connections

• Cure Type: Room temperature or Heat Cure

• Operating Temperature: -60 to 175 °C

• Typical Applications: Fiber optic assembly, multimode and single mode connectors, small potting and sealing applications.

- UNCURED PROPERTIES:

• Viscosity @ 25 °C : 2100

• Specific Gravity: 1.19

• Pot Life: 2 hours

- CURE SCHEDULE:

• 24 hours @ 25°C

• 5 minutes @ 100°C

- CURED PROPERTIES:

• Glass Transition (Tg), ultimate, °C: 120

• Hardness, Shore D: 85

• Refractive Index: 1.54

• Tensile Shear, alum to alum, psi: 2800

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

CALL (888) 522-6742 for more informations.

Color coded Epoxy, High Temperature Adhesive, Fast Cure, Two Part, Fiber Optic Connectors Repair & Assembly, F123, 250gm

- PRODUCT DESCRIPTION:

AA-BOND F123 is a low viscosity, two-component epoxy formulation that signals both proper mixing and curing when bonding fiber optic bundles, potting glass fibers, and/or terminating single or multi-channel fiber optic connectors. Although this unique three-step color-change formulation unmixed components are light yellow, it turns light green on mixing, and changes again to a deep reddish-amber after the REQUIRED 100°C HIGH TEMPERATURE CURE. It exhibits good wicking, and develops strong, tough, mechanically stable bonds to a wide variety of fiber optic and optical materials that includes most metals, ceramics, glass and many plastics.

AA-BOND F123 has good impact and thermal shock resistance, and yields excellent low stress, pot-and-polish connections which do not piston during cycle tests. It is also resistant to water and weathering, vapors and gases, most petroleum products, and an extended range of organic and inorganic environments. Shorter cures at higher temperatures e.g. 2 minutes at 120°C or 1 minute at 150°C are also possible. An additional post-cure of 30 minutes at 150°C is recommended when application temperatures higher than 150°C are anticipated.

- GENERAL PROPERTIES:

+Color: Clear, Light Yellow Unmixed

Clear, Reddish-Brown Cured

+ Components 2 component - requires mixing

+ Mix Ratio by weight 100:10 / Resin:Hardener

+ Benefits

Low viscosity, Thermal shock and impact resistant, Low stress connections, Color coded

- Cure Type: Room temperature or Heat Cure

- Operating Temperature: -60 to 175 °C

- Typical Applications:

Fiber optic assembly, multimode. single mode connectors, small potting, and sealing applications.

- UNCURED PROPERTIES:

Viscosity At 25 °C : 2100

Specific Gravity: 1.19

Pot Life: 2 hours

- CURE SCHEDULE:

24 hours At 25°C

5 minutes At 100°C

- CURED PROPERTIES:

Glass Transition (Tg), ultimate, °C: 120

Hardness, Shore D 85

Refractive Index 1.54

Tensile Shear, alum to alum, psi: 2800

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

CALL (888) 522-6742 for more informations.

Effective Thermal Coupler Grease, Thermally Conductive, For Cooling, thermal management, Telecommunications, Hardware AA-GREASE 04, 1 Kg / 35.8 oz

- PRODUCT DESCRIPTION: AA-GREASE 04 is an opaque white heat sink grease compound, which is applied to the base and mounting studs of transistor and diodes to provide a positive heat sink seal, this facilitates heat transfer away from electrical/electronic components and into heat sinks, thereby increasing the overall efficiency and performance of the device. AA-GREASE 04 is silicone material, heavily filled with efficient heat conductive zinc oxide and a binding agent, this combination promotes high thermal conductivity, high temperature stability, and the lowest amount of bleed and evaporation. AA-GREASE 04 thermal compound resists changes in consistency temperatures up to 180°C; function as heat transfer media, durable dielectric insulation, barrier against environmental contaminants and as a stress-relieving shock and vibration absorber over a wide temperature and humidity range. AA-GREASE 04 thermal paste is resistant to ozone and ultraviolet degradation and has good chemical and solvent stability, good interference between the heat producing device and the heat transfer media, and low surface tension that enables them to wet most surfaces. AA-GREASE 04 will not harden, dry, or melt after 1200 hours @ 205°C. - ELECTRICAL PROPERTIES: Dielectric Strength, volts/mil (ASTM D 150): 390 Dielectric Constant @ 100Hz (ASTM D150): 4.40 Dissipation Factor @ 100Hz (ASTM D150): 0.0021 Volume Resistivity, ohm-cm (ASTM D257): 2.9 x1014 - THERMAL PROPERTIES: Thermal Conductivity W/m-K: 0.88 Operating Temperature Range, °C: -60 to 205 Thermal Resistance °C-In2 /W: 0.05 - LIMITATIONS: AA-GREASE 04 is neither tested nor represented as suitable for medical or pharmaceutical use. - CLEAN UP & DISPOSAL: AA-GREASE 04 can be removed by using solvents such as mineral spirit, heptane, or isopropyl alcohol. Dispose of in accordance with local, state and federal regulations for hazardous waste. - TYPICAL PROPERTIES AND CHEMICAL CHARACTERISTICS: Color: White Base Fluid: Dimethyl Polysiloxane Filler: Zinc oxide Specific Gravity, 25°C, gm/cc: 2.45 Viscosity: Paste Press Flow @ 42.5 PSI, 25°C sec: 13 Penetration (Worked), mm: 2851/10 Evaporation 24 hrs @25°C, %: 0.0 Evaporation @ 200°C 24H by weight, %: 0.5 Bleed 24 Hours, %: 0.6 - STORAGE HANDLING & SHELF LIFE: AA-GREASE 04 has a shelf life of 5 years at room temperature (76°F) in an unopened container, settlings may occur during long term storage, it is recommended to re-mix the filler by hand or mechanical mixing. Keep container tightly closed store in cool area away from ignition sources and oxidizers, no special precautions need to be taken if product is handled according to directions. Shelf AA-GREASE 04 is neither tested nor represented as suitable for medical or pharmaceutical use. - POTENTIAL USES: • Effective thermal coupler for any heat sink device, CPU to heat sink. • Automotive temperature-sensing devices. • Temperature sensors. • Applied to the base and mounting studs of transistor, diodes and silicone controlled rectifiers. • Power transistors. • Diodes, semiconductors. • Thermal Joints. • For any device where efficient cooling is required. • Potting. • TE

Spectroline® - AB-100CS Acid Buster™ injection kit, with 0.5 Oz. Cartridge

ACID-BUSTER™ Injection Kit. Acid Scavenging Solution - Eliminates Acid Buildup in AC & R Systems. Prevents Compressor Burnout! Ideal for small to medium sized systems. Works with all lubricants and systems, including high-pressure R-410A systems. Contains: EZ-50 EZ-Ject™ injector assembly EZ-25 hose assembly complete with check valve and ¼ inch flare low-loss fitting (2) AB-5CS 0.5 oz. ( 14.8 ml) EZ-Ject™ cartridges filled with ACID-BUSTER™ acid scavenging solution.

Metal Repair Epoxy Adhesive, Steel filled, High Performance, AA-BOND FS313, 250 gm pouch

PRODUCT DESCRIPTION:

This Product is steel epoxy, tooling resin features a highly filled, low viscosity composition for low shrinkage,can be easily drilled, tapped, polished, milled, sawed, or turned on a lathe, with conventional metal-working tools. This unique resin system is recommended for the fabrication of metal and vacuum form molds, hammer forms, drop hammer dies, foundry patterns, master molds, core filling, draw and stretch dies, lay-up molds, etc. Easy mix pre-measured pouch. Simple mix and use without any mess.

General Prupose Epoxy Casting, Versatile Formula Adhesive, AA-CAST 156, 250gm kit

PRODUCT DESCRIPTION:

This is an easy-to-use, low cost, versatile epoxy resin and hardener system developed for general purpose casting applications. It develops excellent adhesion to most metals, plastics, and ceramics, and is recommended for electrical and structural potting and encapsulating applications where the combination of good mechanical, thermal, electrical and RT Cure properties are required. Fully cured this product is a strong, tough, electrical insulator with high heat stability and a low thermal coefficient of expansion that provides successful performance over a wide temperature range. It is resistant to industrial environments that include water, weather, galvanic action, petroleum fuels, lubricants and solvents, gases and vapors, many mild acids and alkalis.

Call (888) 522-6742 For More Informations.

High Impact Strength Epoxy For Electronic Industries, PCB, Aerospace, Staking Components, Bonding, Laminating, Repair, 2 Part, 2110, 250gm

- PRODUCT DESCRIPTION:

AA-BOND 2110 is a thixotropic epoxy resin and hardener formulation developed for industrial adhesive, staking, laminating, repair and manufacturing applications where long pot-life, good wetting, non-sag, non-drip and improved impact strength properties are required.

AA-BOND 2110 is easy-to-use two parts adhesive system contains no volatile solvents, readily cures at room temperature, and bonds to most materials including glass and glass fabrics, ceramics, wood, leather, most metals, and many plastics.

AA-BOND 2110 is strong, tough, resilient, has superior mechanical impact and thermal shock resistance characteristics, and is also highly resistant to weather, water, gases and vapors, most petroleum products and fuels, salts, mild acids and alkalis, and many other organic and inorganic compounds.

- GENERAL PROPERTIES:

Appearance: Hazy off white

Cure Type: Room temperature or Heat cure

Benefits: High Impact strength

• Good wetting

• Long pot life

Mix Ratio by weight: 100:30 / Resin:Hardener

Substrates:

Staking components, bonding, laminating, repair applications, metals, glass, ceramics, wood and many plastics

Operating Temperature: -70 to 100 °C

Typical Applications:

PCB components, aerospace, anything where superior properties are required

- UNCURED PROPERTIES:

Specific Gravity, mixed: 1.25 g/cc

Viscosity @25 °C, cps: 65000

Pot Life: 1 hour

- CURE SCHEDULE:

10 hours @ 65°C

24 hours @ 25°C

- MISC PROPERTIES:

Volume Resistivity: 9.30e+8 ohm-cm

Dielectric Constant: 4.7

Dielectric Strength: 430 kV/in

CTE, linear: 30.5 µin/in-°F @ RT

Hardness, Shore D: 80

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

CALL (888) 522-6742 for more information.

TRADEPRO® - TP-LF-00280 A/C Leak Freeze® 1-1/2 oz. Cartridge

TRADEPRO® - AC Leak Freeze® is the leading air conditioning and refrigerant leak repair solution in the US today. All products are OEM approved and made in the USA. AC Leak Freeze is ideal for preventative maintenance and leak protection.

High Strength Epoxy Adhesive, Perfect Bond Glue For Printed Circuit Boards, Wave Guides, Electronic Modules, Flat Cable, Static, EMI & RFI Shielding,

- PRODUCT DESCRIPTION:

AA-DUCT CG2 is a single component epoxy, formulated with silver coated ceramic that results in lower material costs without adversely sacrificing the properties obtained with a pure silver formulation. This concept opens the door to a wide range of applications previously prohibited by the much higher cost of Conventional silver conductive.

AA-DUCT CG2 Formulated with Silver coated ceramic power combined with organic binders and solvents to produce electrically conductive paths, films or patterns over non-conductive substrates.

AA-DUCT CG2 formulation produces electrically conductive paths on a wide variety of surfaces including plastics, rubber, cloth, thermoplastic, paper, wood and many others.

AA-DUCT CG2 designed for use in diversified applications as microwave EMI & RFI shielding, in the assembly or repair of printed circuit boards, waveguides, electronic modules, flat cable, static shielding, connections, and circuitry.

- GENERAL INFORMATION:

Appearance: Silver

Coated ceramic %Silver coated ceramic : 76

Cure Type: Heat cure

Benefits:

- High strength

- Perfect bond

- EMI & RFI shielding

- Wave guides

Substrates: Excellent choice for the Integrated Circuits, aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards.

Catalyst: Anhydride

- CURED PROPERTIES:

Sheet Resistivity:

Nickel Adhesive Electrically Conductive Epoxy, 1 Part, Heat Cure Only, Fast Cure, Ease In Handling, Passes NASA’s Outgassing For EMI RFI Shielding,

- PRODUCT DESCRIPTION: AA-DUCT N02 is a single component, heat curing, conductive epoxy polymer that was designed for ease in handling. This high performance conductive polymer cures quickly at elevated temperatures making it ideally suited for rapid Processing and assembly. AA-DUCT N02 passes NASA’s outgassing testing (ASTM E-595) and is listed in NASA’s Outgassing Data for Selecting Spacecraft Materials list. AA-DUCT N02 offers excellent mechanical, electrical, and physical properties at continuous operating Temperatures up To 175°C. This versatile nickel conductive adhesive can be used for chip bonding in Micro and electronic hybrid circuit Fabrication. This unique conductive polymer also exhibits outstanding adhesion to a wide variety of substrates with good hot strength at intermittent temperatures up to 325°C. AA-DUCT N02 has also been used in microwave applications for EMI and FRI shielding, for assembly and repair of circuit boards and Electronic component manufacturing. - PRODUCT DESCRIPTION: Base: Epoxy Appearance: Grey Cure Type: Heat cure or Room temperature Mix Ratio by weight: 100:6 / Resin: Hardener Substrates Excellent choice aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards. Operating Temperature: -60 to 110 °C Viscosity @ 25 °C cps Soft: Paste Shelf Life: 6 months - CURED PROPERTIES: Hardness, Shore D: 88 Volume Resistivity ohm-cm: 3.8 x 10-2 - CURE SCHEDULE: 2 Hours @ 125 °C 1 hour @ 150°C 30 min @ 175 °C - THERMAL CHARACTERISTICS: Thermal Conductivity, Btu/hr/ft2/°F/in: 10.1 Operating Temp. Range, °C: -55 to +175 - NASA OUTGASSING RESULTS: TML (Total Mass Loss): % 0.25 CVCM (Collected Volatile Condensable Materials): % 0.00 WVR (Water Vapor Recovery): % 0.07 - GENERAL INFORMATION: For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS). - AVAILABILITY: This epoxy can be supplied in various different packages. - PRODUCT DESCRIPTION: AA-DUCT CG2 is a single component epoxy, formulated with silver coated ceramic that results in lower material costs without adversely sacrificing the properties obtained with a pure silver formulation. This concept opens the door to a wide range of applications previously prohibited by the much higher cost of Conventional silver conductive. AA-DUCT CG2 Formulated with Silver coated ceramic power combined with organic binders and solvents to produce electrically conductive paths, films or patterns over non-conductive substrates. AA-DUCT CG2 formulation produces electrically conductive paths on a wide variety of surfaces including plastics, rubber, cloth, thermoplastic, paper, wood and many others. AA-DUCT CG2 designed for use in diversified applications as microwave EMI & RFI shielding, in the assembly or repair of printed circuit boards, waveguides, electronic modules, flat cable, static shielding, connections, and circuitry. - GENERAL INFORMATION: Appearance: Silver Coated ceramic %Silver coated ceramic: 76 Cure Type: Heat cure Benefits: - High strength - Perfect bond - EMI & RFI shielding - Wave guides Substrates: Excellent choice f

Two Part Epoxy Long Pot Life, Impact Resistant For Fiber Optic Assembly Multimode & Single Mode Connectors, Small Potting & Sealing Applications F112,

- PRODUCT DESCRIPTION:

AA-BOND F112 is an impact resistant, fiber-optic adhesive.

AA-BOND F112 is two-part, low viscosity epoxy has the distinct advantage of remaining below 3000 cps for a minimum of 40 minutes.

AA-BOND F112 allows more connectors to be produced from one mix. Low stress, AA-BOND F112 is an excellent choice for multimode connectors and single mode connectors where excessive curing temperatures may cause cracking.

AA-BOND F112 can be cured at room temperature overnight or as fast as 15 minutes at 90°C. The blue color facilitates easy polishing and its cured properties prevent pistoning. This product is a 100% solid system that can be used for small potting and sealing applications where resistance to thermal shock and impact are required.

- GENERAL PROPERTIES

• Appearance: Blue

• Components: 2 component - requires mixing

• Mix Ratio by weight: 100:30 / Resin:Hardener

• Benefits:

o Low viscosity

o Thermal shock and impact resistant

o Low stress connections

• Cure Type: Room temperature or Heat Cure

• Operating Temperature : -60 to 100 °C

• Typical Applications:

Fiber optic assembly, multimode and single mode connectors, small potting and sealing applications

- UNCURED PROPERTIES:

Viscosity @ 25 °C: 2300

Thixotropic Index: 1.0

Specific Gravity, cured: 1.2

Pot Life: 30 minutes

- CURE SCHEDULE:

24 hours @ 25°C

1 hour @ 65°C

15 minutes @ 90°C

- CURED PROPERTIES:

Glass Transition Temperature (Tg), ultimate, °C: 102

Hardness, Shore D: 85

Refractive Index: 1.51

Water Absorption , after 24 hours saturation, %: 0.07

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

CALL (888) 522-6742 for more informations.

Epoxy Adhesive Optically Clear, Low Viscosity High Impact Potting, 2 part, AA-BOND F117, 250gm Jar

This is an optically clear, low viscosity, high impact epoxy adhesive developed for bonding and small volume potting of plastic or glass optical fibers, lenses, and prisms, LED displays, and other optical components. It is recommended for laminating, bonding, and sealing applications where excellent wetting, good pot life and improved impact strength properties are required. This two part adhesive is easily mixed and cured at room temperature, and develops strong, tough bonds to glass and glass fibers, ceramics, many metals, and most rigid plastics. This product bonds offer resistance to mechanical impact and thermal shock, and are also resistant to weather, water, gases and vapors, petroleum products, salts, and mild acids and alkalis. Easy mix pre-measured pouch. Simple mix and use without any mess.

Rectorseal - AC Leak Freeze® Leak sealant & system enhancer

Leak sealant and system enhancer for A/C and refrigeration systems Country of Origin: USA Application: AC and Refrigeration Systems Brand: Rectorseal & reg; Color: Green Functions: Extends Compressor Life and Reduces Noise - Improves AC System Lubrication and Reduces Friction - Cleans and Revitalizes the AC System - Reduces Energy Consumption - Enhances the Performance of Older AC Systems Prop 65: No Shelf Life: 2 YRS Size: 1.5 oz. cartridge Tier: AC Leak Freeze & reg;

Clear Epoxy Solvent Free, Low Viscosity, Good Wetting For Fiber Optic, Electronic, Aerospace, Laminating 2113, 250gm

- PRODUCT DESCRIPTION:

AA-BOND 2113 is a clear, low viscosity epoxy adhesive system that contains no solvents, cures at room temperature, has excellent flow ability and wetting characteristics, and adheres strongly to glass, ceramics, most metals and many plastics.

AA-BOND 2113 is particularly recommended for assembly and repair work of fiber optic and other high performance electronic and aerospace systems and components, and for structural laminating applications where an initial low viscosity and near transparent "color" are needed.

AA-BOND 2113 is a good electrical insulator, provides excellent resistance to weather, galvanic action, salt solutions and many other chemicals including mild acid and alkalis, petroleum solvents, lubricating oils, jet fuels and gasoline, and alcohol.

- GENERAL PROPERTIES:

• Appearance Clear transparent

• Cure Type Room temperature or Heat Cure

• Benefits:

o Good wetting

o Solvent free

o Excellent flowability

o Adheres strongly to numerous substrates

• Mix Ratio by weight: 100:11 / Resin:Hardener

• Substrates:

Ceramics, glass to glass, fabrics, metals, laminates and other composite materials

• Operating Temperature: -60 to 130 °C

- UNCURED PROPERTIES:

• Specific Gravity: 1.15

• Reactive solids contents, %: 100

• Pot Life: 30 minutes

- CURE SCHEDULE:

• 4 hours @ 65°C

• 24 hours @ 25°C

- MISC PROPERTIES:

• Volume Resistivity: 6.00e+13 ohm-cm

• Dielectric Constant: 4.2

• Dielectric Strength: 410 volts/mil

• Hardness, Shore D: 88

• Dissipation factor: 0.020

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

CALL (888) 522-6742 for more information.

Pure Silver Conductive Epoxy, Maximum Continuity Of Conductivity For Rear Window Defroster Repair, Grid Repair, Cold Solder, Electronic Bonding, Or Se

Window Defroster Grid Repair Kit: The Window Defroster Grid Repair kit is an epoxy adhesive and coating formulation based on pure silver. This versatile silver formulation offers the maximum continuity of conductivity with an electrical resistivity value of less than 1x10-4 ohm. cm. Our Defroster/Window Grid Repair kit is also characterized by a wide operating temperature range from –50 to +170°C. This Defroster/Window Grid Repair kit is recommended for grid repair, electronic bonding, or sealing applications that require both fine electrical and mechanical properties. It can Substrates also aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards. Put the measuring lead (Red) and the reference (Black) of the Multimeter on the damaged grid line at both ends, right where the grid connects with the wide bus bars. Move one probe--it doesn't matter which--to the center of the line. If you now read 6 volts, the scratch is not in between the two probes. If you read the same system voltage, 12 volts or so, the break is in between the old probe location and the new one. Just move the probes until you find the location that has full system voltage spanning it. Now it's time to turn off the de¬froster grid and the ignition switch. How To Repair The Defroster Tab: Clean the tab and the contact area with the alcohol prep. Then apply activator to both surfaces and let it dry. Apply the completely mixed adhesive kit to the prepared surfaces, and gently press these surfaces together. Contact pressure is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured. Press the tab onto the contact area. Hold it in place until the adhesive sets up, usually about two minutes. Wait 24 hours to use the defogger. Defroster TABS: The tabs located along the sides of the defroster connect the defroster electrically to the vehicles defrost circuit. One tab is the positive and the other ground. If a tab comes off the defroster this will mean total instantaneous failure of the defroster. Our kit is an epoxy adhesive. To use, carefully clean and dry all surfaces to be bonded from all dirt, dust, debris and handprints from the rear window. Apply the completely mixed adhesive kit to the prepared surfaces, and gently press these surfaces together. Contact pressure is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured. Some separation of components is common during shipping and storage. For this reason, it is recommended that the contents of the shipping container be thoroughly mixed prior to use. Some ingredients in this formulation provided may crystallize when subjected to low temperature storage. A gentle warming cycle of 52°C for 30 minutes prior to mixing components may be necessary. Crystallized epoxy components do not react as well as liquid components and should be re-dissolved prior to use for best results. Misc Properties: Hardness, Shore D 83 Shrinkage linear in/in 0.003 Lap shear strength, psi 9400 Volume Resistivity ohm cm = 0.0001 Cure Schedule: 2 minutes @ 120°C 5 minutes

Totaline® - P902-39001 Totalfresh Odor Neutralizer (1/2 Lb. Tub)

TotalFresh is a long lasting odor neutralizer that removes odors from the air. It is not a perfume or masking agent.

Super Electrically Conductive Silver Epoxy For Static and EMI RFI Shield, Wave Guides, PCB, IC, Electronic Modules, Flat Cable, 1 Part, 905, 50gm

- PRODUCT DESCRIPTION: AA-DUCT 905 is a single component epoxy, formulated with pure silver powder combined with organic binders and solvents to produce electrically conductive paths, films or patterns over non-conductive substrates. AA-DUCT 905 shows slight settling when stored for a long period of time, no caking and will re disperse to a smooth homogeneous state. AA-DUCT 905 formulation produces electrically conductive paths on a wide variety of surfaces including plastics, rubber, cloth, thermoplastic, paper, wood and many others. AA-DUCT 905 designed for use in diversified applications as microwave EMI & RFI shielding, in the assembly or repair of printed circuit boards, wave-guides, electronic modules, flat cable, static shielding, connections, and circuitry. This Epoxy is designed for screening and micro product adhesion applications. - PRODUCT PROPERTIES: Appearance: Silver Cure Type: Heat cure Benefits: * High strength * Perfect bond * EMI & RFI shielding * Wave guides Substrates: * Integrated Circuits * Aluminum * Copper * Magnesium * Steel * Bronze * Nickel * Kovar * Ceramic * Glass * Phenolic * G-10 epoxy glass boards. Catalyst: Anhydride Hardness, Shore D: 83 - AVAILABILITY: This epoxy can be supplied in many different packages. CALL (888) 522-6742 for more informations.

Super Electrically Conductive Silver Epoxy For IC, Electronic Modules, Flat Cable, Static Shielding, Connections & Circuitry, One Part 905-5gm

- PRODUCT DESCRIPTION:

AA-DUCT 905 is a single component epoxy, formulated with pure silver powder combined with organic binders and solvents to produce electrically conductive paths, films or patterns over non-conductive substrates.

AA-DUCT 905 shows slight settling when stored for a long period of time, no caking and will re disperse to a smooth homogeneous state.

AA-DUCT 905 formulation produces electrically conductive paths on a wide variety of surfaces including plastics, rubber, cloth, thermoplastic, paper, wood and many others.

AA-DUCT 905 designed for use in diversified applications as microwave EMI & RFI shielding, in the assembly or repair of printed circuit boards, wave-guides, electronic modules, flat cable, static shielding, connections, and circuitry. This Epoxy is designed for screening and micro product adhesion applications.

- PRODUCT PROPERTIES:

Appearance : Silver

Cure Type: Heat cure

Benefits:

• High strength

• Perfect bond

• EMI & RFI shielding

• Wave guides

Substrates:

• Integrated Circuits

• Aluminum

• Copper

• Magnesium

• Steel

• Bronze

• Nickel

• Kovar

• Ceramic

• Glass

• Phenolic

• G-10 epoxy glass boards.

Catalyst: Anhydride

Hardness, Shore D: 83

- AVAILABILITY:

This epoxy can be supplied in many different packages.

CALL (888) 522-6742 for more informations.

Good Electrical Insulation Epoxy For PCB Staking Electronics Aerospace Industrial Bonding Laminating Repair Applications 2112, 250gm

- PRODUCT DESCRIPTION: AA-BOND 2112 is a thixotropic epoxy system recommended for critical electronics, aerospace and industrial bonding, laminating and reinforcing applications requiring an adhesive with high-fill, non-sag characteristics. AA-BOND 2112 solvent-free adhesive is easily mixed and used for staking components to printed circuit boards for enhanced mechanical rigidity, and for bonding, laminating and repair applications involving metals, glass, ceramics, wood and many plastics. AA-BOND 2112 hardens to a tough, enamel-like coating offering good chemical resistance as well as superior physical and mechanical properties. The cured adhesive provides good electrical insulation and resistance to weather, galvanic action, petroleum products and lubricants, alcohol, salts, mild acids and alkalis, and other organic and inorganic compounds. - GENERAL PROPERTIES: * Appearance: Milky translucent * Cure Type: Room temperature or Heat Cure * Benefits: o Tough enamel like cure o Bonds variety of substrates o Good electrical insulation o Weather resistant Mix Ratio by weight: 100:22 / Resin: Hardener Substrates: Metals, glass, ceramics, wood and many plastics Operating Temperature: -60 to 125 °C Typical Applications: Printed circuit board repair, staking components, bonding, laminating and repair applications. - UNCURED PROPERTIES: Viscosity @ 25 °C, mPa·s (cP): 60000 cPs Thixotropic Index: 6.5 Specific Gravity, mixed: 1.2 Reactive solids contents, %: 100 Pot Life: 30 minutes - CURE SCHEDULE: 4 hours @ 65°C 24 hours @ 25°C - MISC PROPERTIES: * Volume Resistivity 6.00 e+13 ohm-cm * Dielectric Constant 4.6 * Dielectric Strength 16.1 kV/in * CTE, linear: 55.0 µm/m-°C @ Temperature 20.0 °C * Glass Transition Temp, Tg: 93 °C * Hardness, Shore D: 90 * Lap shear: 1900 psi (Alum to Alum) - GENERAL INFORMATION: For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS). - AVAILABILITY: This epoxy can be supplied in various different packages. CALL (888) 522-6742 for more information.

Pure Silver Conductive Epoxy, Maximum Continuity Of Conductivity For Rear Window Defroster Repair, Grid Repair, Cold Solder, Electronic Bonding, Or Se

Window Defroster Grid Repair Kit: The Window Defroster Grid Repair kit is an epoxy adhesive and coating formulation based on pure silver. This versatile silver formulation offers the maximum continuity of conductivity with an electrical resistivity value of less than 1x10-4 ohm. cm. Our Defroster/Window Grid Repair kit is also characterized by a wide operating temperature range from –50 to +170°C. This Defroster/Window Grid Repair kit is recommended for grid repair, electronic bonding, or sealing applications that require both fine electrical and mechanical properties. It can Substrates also aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards. Put the measuring lead (Red) and the reference (Black) of the Multimeter on the damaged grid line at both ends, right where the grid connects with the wide bus bars. Move one probe--it doesn't matter which--to the center of the line. If you now read 6 volts, the scratch is not in between the two probes. If you read the same system voltage, 12 volts or so, the break is in between the old probe location and the new one. Just move the probes until you find the location that has full system voltage spanning it. Now it's time to turn off the de¬froster grid and the ignition switch. How To Repair The Defroster Tab: Clean the tab and the contact area with the alcohol prep. Then apply activator to both surfaces and let it dry. Apply the completely mixed adhesive kit to the prepared surfaces, and gently press these surfaces together. Contact pressure is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured. Press the tab onto the contact area. Hold it in place until the adhesive sets up, usually about two minutes. Wait 24 hours to use the defogger. Defroster TABS: The tabs located along the sides of the defroster connect the defroster electrically to the vehicles defrost circuit. One tab is the positive and the other ground. If a tab comes off the defroster this will mean total instantaneous failure of the defroster. Our kit is an epoxy adhesive. To use, carefully clean and dry all surfaces to be bonded from all dirt, dust, debris and handprints from the rear window. Apply the completely mixed adhesive kit to the prepared surfaces, and gently press these surfaces together. Contact pressure is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured. Some separation of components is common during shipping and storage. For this reason, it is recommended that the contents of the shipping container be thoroughly mixed prior to use. Some ingredients in this formulation provided may crystallize when subjected to low temperature storage. A gentle warming cycle of 52°C for 30 minutes prior to mixing components may be necessary. Crystallized epoxy components do not react as well as liquid components and should be re-dissolved prior to use for best results. Misc Properties: Hardness, Shore D 83 Shrinkage linear in/in 0.003 Lap shear strength, psi 9400 Volume Resistivity ohm cm = 0.0001 Cure Schedule: 2 minutes @ 120°C 5 minutes

Good Wetting Epoxy, High Temperature, Fast Cure, Low Viscosity For Industrial & Sealing Applications, 2 Part, FS227, 100gm

- PRODUCT DESCRIPTION:

AA-BOND FS227 is a thixotropic polymer epoxy/polyamide system developed for industrial adhesive and sealing applications where the combination of high fill, easy handling, good wetting, toughness, and superior mechanical properties are required.

- GENERAL PROPERTIES

Appearance: Amber

Cure Type: Heat cure or Room temperature

Benefits:

+ High fill

+ Easy handling

+ Good wetting

+ Toughness

+ High temperature

+ Fast cure

+ Low viscosity

Operating Temperature: -60 to 110 °C

Substrates: Most material surfaces, including many metals, rigid plastics, glass, ceramics, leather, rubber, wood and concrete

- UNCURED PROPERTIES:

Viscosity @ 25 °C: 650

Specific Gravity, mixed: 1.12 g/cc

Pot Life: 75 minutes

- CURE SCHEDULE:

4 hours @ 65°C

24 hours @ 25°C

- CURED PROPERTIES:

Volume Resistivity: 1.20e+14 ohm-cm

Dielectric Strength: 460 volts/mil

Glass Transition Temp, Tg: 70 °C

Dielectric Constant: 3.35 @ Frequency 1000 Hz

Hardness, Shore D: 75

Lap shear: 2500 psi (Alum to Alum)

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

Call (888) 522-6742 For More Informations.

FDA Medical Grade Adhesive, Low Permeability & Viscosity Epoxy, Good Resistance, Electrical Insulator for Bonding & Coating Applications 2 Part, FDA15

- PRODUCT DESCRIPTION:

AA-BOND FDA15 is a low viscosity epoxy resin system specifically developed for bonding and coating applications in accordance with Title 21, U.S. Code of Federal Regulations, Food and Drug Administration Chapter 1, Sub Part B, Sections 175.105 and 175.300.

AA-BOND FDA15 is two-part adhesive is used for bonding, laminating and repair applications by manufacturers of food preparation, processing and packaging equipment, and by manufacturers of catheters, hearing aids, dental products and other biomedical instruments and devices.

AA-BOND FDA15 is an effective electrical insulator, and it provides low permeability to gases and vapors and good resistance to water, weather, galvanic action, to petroleum solvents, lubricants and fuels, to mild acids and alkalis, and to many other organic and inorganic compounds.

- GENERAL PROPERTIES:

• Appearance Clear

• Cure Type Heat cure or Room temperature

• Benefits:

* Low viscosity

* Good resistance

* Effective electrical insulator

* Low permeability

Mix Ratio by weight 100:20 / Resin:Hardener

• Substrates:

* Most metals

* Ceramic

* Glass and plastics

* Operating Temperature -60 to 140 °C.

- Typical Application:

Developed for bonding and coating applications.

- UNCURED PROPERTIES:

Viscosity At 25 °C 4,300 Thixotropic Index 1.0 Specific Gravity, mixed 1.16 g/cc Reactive solids contents, % 100Pot Life 25 minutes.

- CURE SCHEDULE:

• 1-4 hours At 65°C

• 24 hours At 25°C.

- CURED PROPERTIES:

Glass transition temperature (Tg), °C 100 Hardness, Shore D 87Water Absorption, % 0.23Dielectric strength, Volts/mil 420Lap shear strength, psi 2000 (Alum to Alum).

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

Call (888) 522-6742 For More Informations.

Flexible Epoxy Adhesive For Automotive, Medical, Aerospace, Photonic, Assembly Industries, Plastic Bonder, Plastic Repair 2170, 100gm kit

- PRODUCT DESCRIPTION:

AA-BOND 2170 is a flexible thixotropic bonding adhesive designed for bonding all types of plastics including nylon, PVC, polyethylene, acrylic, lexan, kapton or almost any thermoplastic substrate. AA-BOND 2170 is low viscosity and easy to apply, can cure at room temperature.

AA-BOND 2170 is high technology epoxy was formulated for applications in the automotive, medial, aerospace, photonic and assembly industries and can be used anywhere that require excellent chemical fastening to plastic parts.

- GENERAL PROPERTIES:

Appearance: Amber

Cure Type: Room temperature or Heat cure

Benefits:

Low viscosity

Easy to apply