Trusted shipping

Easy returns

Secure shopping

Buy Color coded Epoxy, High Temperature Adhesive, Fast Cure, Two Part, Fiber Optic Connectors Repair & Assembly, F123, 250gm in United States - Cartnear.com

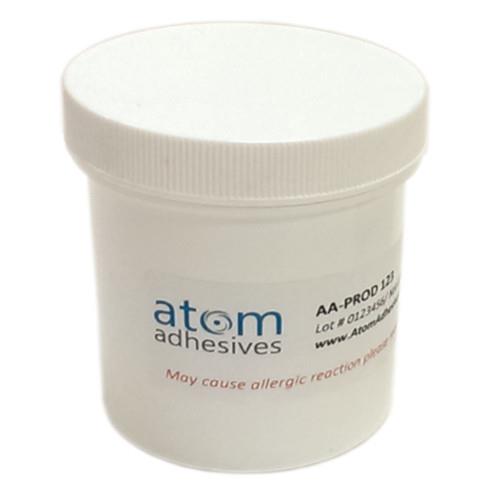

Color coded Epoxy, High Temperature Adhesive, Fast Cure, Two Part, Fiber Optic Connectors Repair & Assembly, F123, 250gm

CTNR1264013 CTNR1264013Atom Adhesives

2027-01-12

/itm/color-coded-epoxy-high-temperature-adhesive-fast-cure-two-part-fiber-optic-connectors-repair-assembly-f123-250gm-1264013

USD

165.99

$ 165.99 $ 169.38 2% Off

Item Added to Cart

customer

*Product availability is subject to suppliers inventory

SHIPPING ALL OVER UNITED STATES

100% MONEY BACK GUARANTEE

EASY 30 DAYSRETURNS & REFUNDS

24/7 CUSTOMER SUPPORT

TRUSTED AND SAFE WEBSITE

100% SECURE CHECKOUT

| Brand | Atom Adhesives |

|---|---|

| Model | AA-BOND F123-250 |

| Type | Adhesives |

| Application | Fiber optic assembly, multimode and single mode connectors, small potting and sealing applications. |

| Features | Low viscosity, Thermal shock and impact resistant, Low stress connections, Color coded |

- PRODUCT DESCRIPTION:

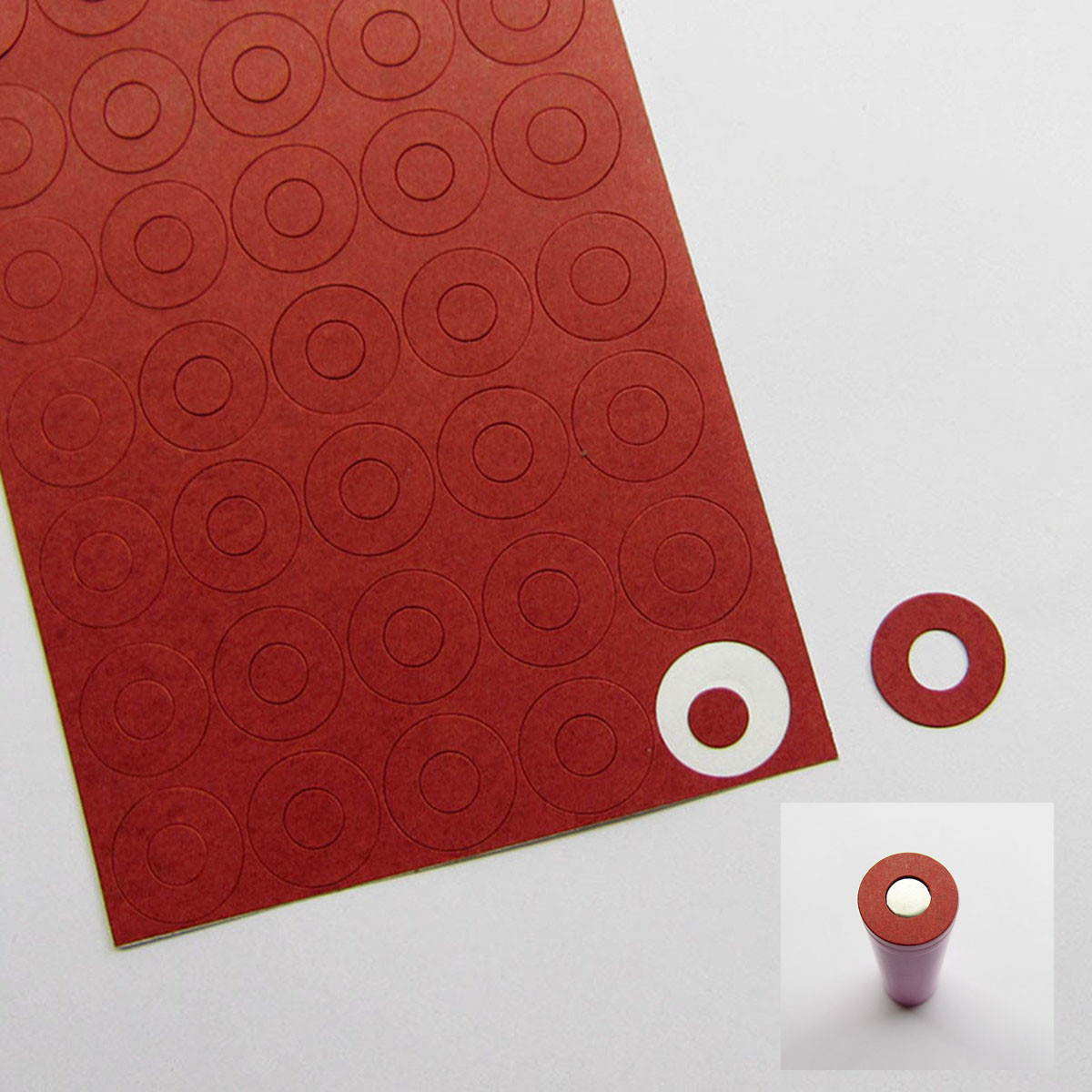

AA-BOND F123 is a low viscosity, two-component epoxy formulation that signals both proper mixing and curing when bonding fiber optic bundles, potting glass fibers, and/or terminating single or multi-channel fiber optic connectors. Although this unique three-step color-change formulation unmixed components are light yellow, it turns light green on mixing, and changes again to a deep reddish-amber after the REQUIRED 100°C HIGH TEMPERATURE CURE. It exhibits good wicking, and develops strong, tough, mechanically stable bonds to a wide variety of fiber optic and optical materials that includes most metals, ceramics, glass and many plastics.

AA-BOND F123 has good impact and thermal shock resistance, and yields excellent low stress, pot-and-polish connections which do not piston during cycle tests. It is also resistant to water and weathering, vapors and gases, most petroleum products, and an extended range of organic and inorganic environments. Shorter cures at higher temperatures e.g. 2 minutes at 120°C or 1 minute at 150°C are also possible. An additional post-cure of 30 minutes at 150°C is recommended when application temperatures higher than 150°C are anticipated.

- GENERAL PROPERTIES:

+Color: Clear, Light Yellow Unmixed

Clear, Reddish-Brown Cured

+ Components 2 component - requires mixing

+ Mix Ratio by weight 100:10 / Resin:Hardener

+ Benefits

Low viscosity, Thermal shock and impact resistant, Low stress connections, Color coded

- Cure Type: Room temperature or Heat Cure

- Operating Temperature: -60 to 175 °C

- Typical Applications:

Fiber optic assembly, multimode. single mode connectors, small potting, and sealing applications.

- UNCURED PROPERTIES:

Viscosity At 25 °C : 2100

Specific Gravity: 1.19

Pot Life: 2 hours

- CURE SCHEDULE:

24 hours At 25°C

5 minutes At 100°C

- CURED PROPERTIES:

Glass Transition (Tg), ultimate, °C: 120

Hardness, Shore D 85

Refractive Index 1.54

Tensile Shear, alum to alum, psi: 2800

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

CALL (888) 522-6742 for more informations.