Trusted shipping

Easy returns

Secure shopping

Buy Perfect Bond Epoxy For EMI & RFI Shielding, PCB, Wave Guides, Electronic Modules, Flat Cable, Shields, Connections, Circuitry, Cold Solder 906, 250gm in United States - Cartnear.com

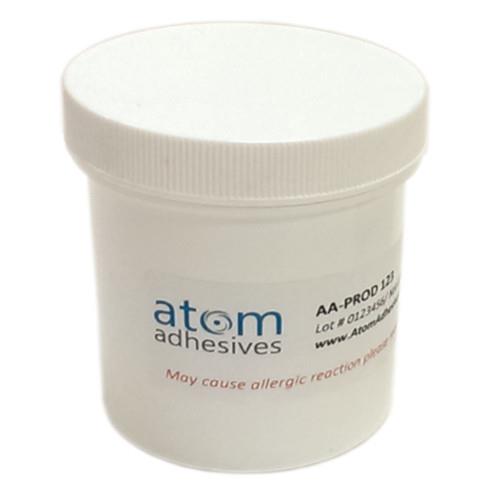

Perfect Bond Epoxy For EMI & RFI Shielding, PCB, Wave Guides, Electronic Modules, Flat Cable, Shields, Connections, Circuitry, Cold Solder 906, 250gm

CTNR1070948 CTNR1070948Atom Adhesives

2027-02-23

/itm/perfect-bond-epoxy-for-emi-rfi-shielding-pcb-wave-guides-electronic-modules-flat-cable-shields-connections-circuitry-cold-solder-906-250gm-1070948

USD

328.77

$ 328 $ 335 2% Off

Item Added to Cart

customer

*Product availability is subject to suppliers inventory

SHIPPING ALL OVER UNITED STATES

100% MONEY BACK GUARANTEE

EASY 30 DAYSRETURNS & REFUNDS

24/7 CUSTOMER SUPPORT

TRUSTED AND SAFE WEBSITE

100% SECURE CHECKOUT

| Brand | Atom Adhesives |

|---|---|

| Model | AA-DUCT 906-250 |

| Type | Adhesives |

| Color/Finish | Silver |

| Application | microwave EMI and RFI shielding, in the assembly or repair of printed circuit boards, wave guides, electronic modules, flat cable, high frequency shields, connections, and circuitry and as a cold solder. |

| Features | High strength, perfect bond, Emi & Rfi shielding, cold solder |

- PRODUCT DESCRIPTION:

AA-DUCT 906 represents the newest technology since the introduction of electrically conductive silver compounds. This unique formulation is based on a silver coated ceramic that results in lower material costs without adversely sacrificing the properties obtained with a pure silver formulation. This concept opens the door to a wide range of applications previously prohibited by the much higher cost of conventional silver conductive.

AA-DUCT 906 cures at room temperature or can be accelerated with mild heat to form a tenacious bond between similar and dissimilar substrates such as aluminum, copper, magnesium, steel, bronze nickel, ceramic, glass, phenolic, and G-10 epoxy glass boards.

AA-DUCT 906, because of its excellent continuity, has been used extensively in such diversified applications as, microwave EMI and RFI shielding, in the assembly or repair of printed circuit boards, wave guides, electronic modules, flat cable, high frequency shields, connections, and circuitry and as a cold solder. This unique formulation offers ease in handling due to its creamy consistency and versatile application by hand, automatic dispenser, silk-screening, transfer or stamping techniques.

- PRODUCT PROPERTIES:

Appearance Silver

Cure Type Heat cure or Room temperature

Benefits:

+ High strength

+ Perfect bond

+ EMI & RFI shielding

+ Cold Solder

Substrates: Excellent choice aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards.

- UNCURED PROPERTIES:

Viscosity @ 25 °C cps Paste

Silver coated ceramic , % 50 to 75

Pot Life @ RT 1 Hour

Mix ratio, by weight 100:5 / Resin:Hardener

Shelf life 1 Year

- CURE SCHEDULE:

15 minutes @ 100°C

30 minutes @ 60°C

24 hours @ Room temperature

- CURED PROPERTIES:

Volume Resistivity: < 0.0015

Hardness, Shore D: 81

Compressive Strength, psi: 13,600

Shrinkage Linear, in / in: 0.004

Specific Gravity, 25°C / 25°C: 2.60

Tensile Strength, psi: 8,900

Compressive Strength, psi: 13,700

- THERMAL PROPERTIES:

Thermal Conductivity, btu / hr / ft2 / °F / in 90

Thermal Expansion Coefficient, (cm / cm / °C • 10-5) 1.9

Heat Distortion, °C 90

Operating Temperature Range, °C -50 to +165

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

Call (888) 522-6742 For More Informations.