Trusted shipping

Easy returns

Secure shopping

Buy High Temperature Epoxy, Water Resistant Glue, Good Impact & Thermal Shock Resistance, Low Viscosity For Fiber Optic & Optical Materials 2 Part, F253, 250gm in United States - Cartnear.com

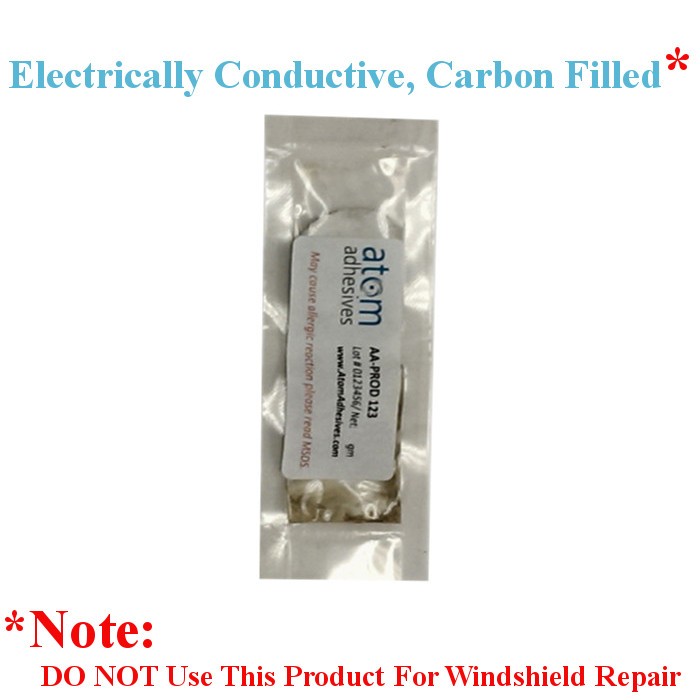

High Temperature Epoxy, Water Resistant Glue, Good Impact & Thermal Shock Resistance, Low Viscosity For Fiber Optic & Optical Materials 2 Part, F253, 250gm

CTNR1101943 CTNR1101943Atom Adhesives

2027-01-12

/itm/high-temperature-epoxy-water-resistant-glue-good-impact-thermal-shock-resistance-low-viscosity-for-fiber-optic-optical-materials-2-part-f253-250gm-1101943

USD

77.3

$ 77.30 $ 78.08 1% Off

Item Added to Cart

customer

*Product availability is subject to suppliers inventory

SHIPPING ALL OVER UNITED STATES

100% MONEY BACK GUARANTEE

EASY 30 DAYSRETURNS & REFUNDS

24/7 CUSTOMER SUPPORT

TRUSTED AND SAFE WEBSITE

100% SECURE CHECKOUT

| Brand | Atom Adhesives |

|---|---|

| Model | AA-BOND F253-250 |

| Type | Adhesives |

| Application | Wide variety of fiber optic and optical materials |

| Features | Good impact and thermal shock resistance, demonstrates low stress, yields excellent pot and polish connections, it is also resistant to water and weathering, vapors and gases, low viscosity, high temperature |

- PRODUCT DESCRIPTION:

AA-BOND F253 is a low viscosity, high temperature, two-part epoxy formulation that changes color during the curing process to indicate cure status.

- GENERAL PROPERTIES:

Appearance Unmixed - Ligh Yellow

Mixed: Greenish Blue

Cured: Reddish Amber

Cure Type: Room Temperatue or Heat cure

Benefits:

* Good impact and thermal shock resistance

* Demonstrates low stress

* Yields excellent pot and polish connections

* It is also resistant to water and weathering, vapors and gases

* Low viscosity

* High temperature

Mix Ratio by weight : 100:10 / Resin:Hardener

Substrates:

Wide variety of fiber optic and optical materials that includes most metals, ceramics, glass and many plastics

Operating Temperature: -60 to 165 °C

- UNCURED PROPERTIES:

Viscosity @ 25 °C : 1800

Thixotropic Index: 1.0

Specific Gravity, mixed: 1.19

Reactive solids contents, %: 100

Pot Life: 1 hour

- CURE SCHEDULE:

15 minutes @ 100°C

5 minutes @ 125°C

1 minute @ 150°C

- CURED PROPERTIES:

Coefficient of thermal expansion ppm/°C Below Tg: – 2.03x1002

Above Tg : – 6.24x1001

Glass transition temperature (Tg), °C: 116

Hardness, Shore D: 88

Refractive Index: 1.56

Water Absorption, %: .004

Lap shear strength, psi: 2700 (Aluminum to Aluminum)

- GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

- AVAILABILITY:

This epoxy can be supplied in various different packages.

Call (888) 522-6742 For More Informations.